- Welcome to Metal Type Forum.

Metal Type: Home | Library | Forum | Free Ads | Store

Posted by Dave Hughes

- February 20, 2010, 04:12:28 PMRobin Kenworthy contacted me via email to add the following:

Quote

They need to read Typographical Printing Surfaces, Legros and Grant 1916, pages 193 to 240 cover punch cutting and mats.

A quick check at Open Book lists several libraries that hold a copy and the last on ebay made $211, as I said before my copy will fall apart if I open flat to scan.

Posted by jhenry

- February 17, 2010, 10:10:24 PMI have sent Dave Hughes some pictures of some of the equipment used to produce mats by engraving. It may take him a while to get them posted ot the site, so when I do see them, I will try to describe the process and further describe the machines involved as best I can remember them.

I would be excited to hear from others who have engraved or stamped mats, and particularly from anyone who is hoping to develop the skills involved.

I've added John's pics to his post, they have a brief description on the pic, but I'll let John explain more fully - Admin

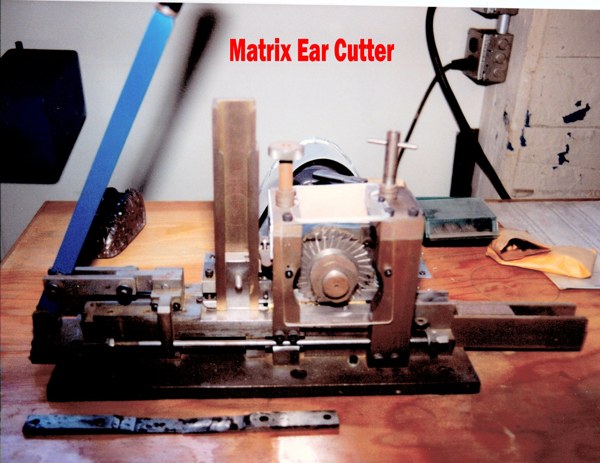

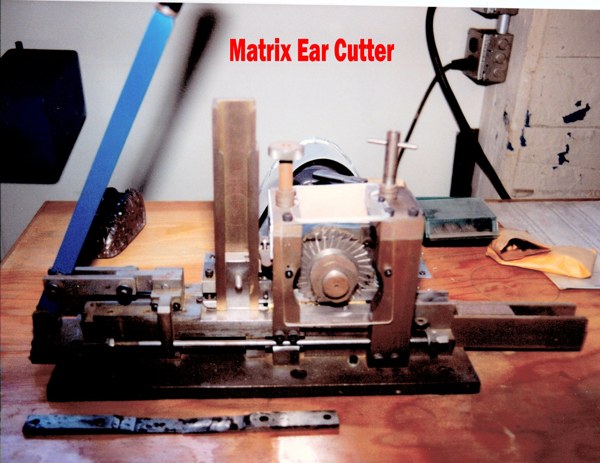

This was used to reduce the thickness of the matrix ears (lino) in order to run correctly thorugh the magazine. The mats were stacked in the magazine and pushed indivudually through under the cutters by moving the lever on the left.

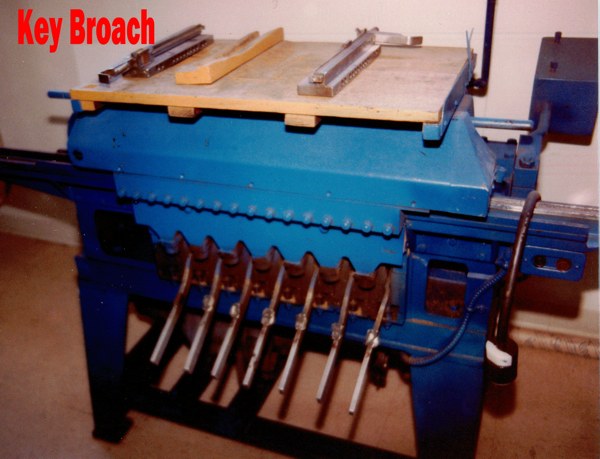

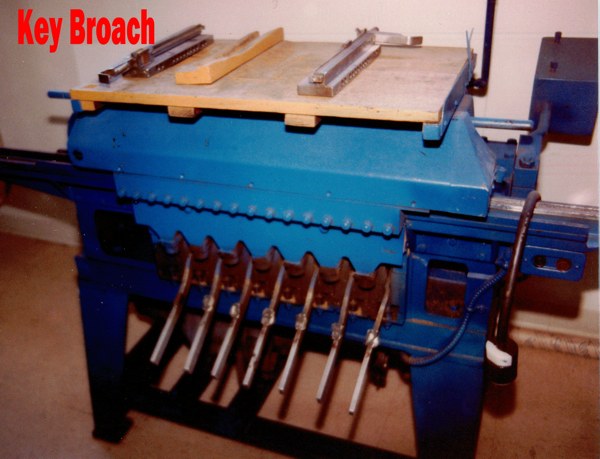

This was the broach used to create the proper key combination on linecaster mats. The levers were raised or lowered in various combinations for the particular characters being cut at the time. The mats were put in the carriers and then pushed through the broach to cut the combinations.

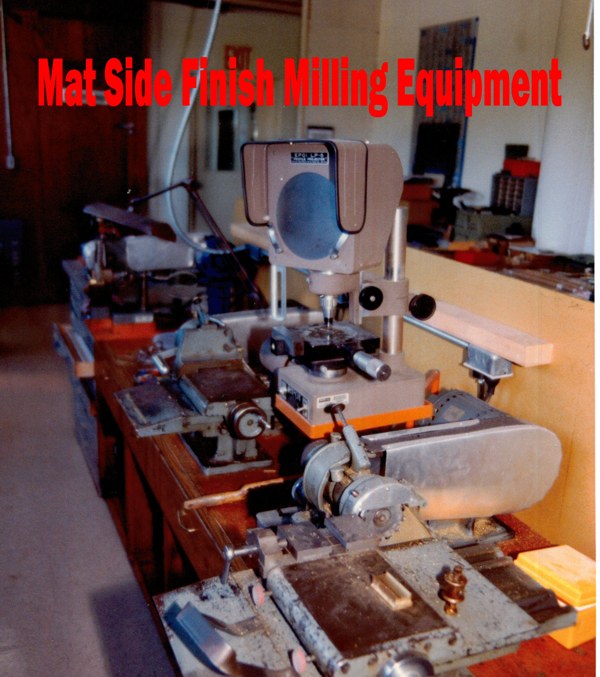

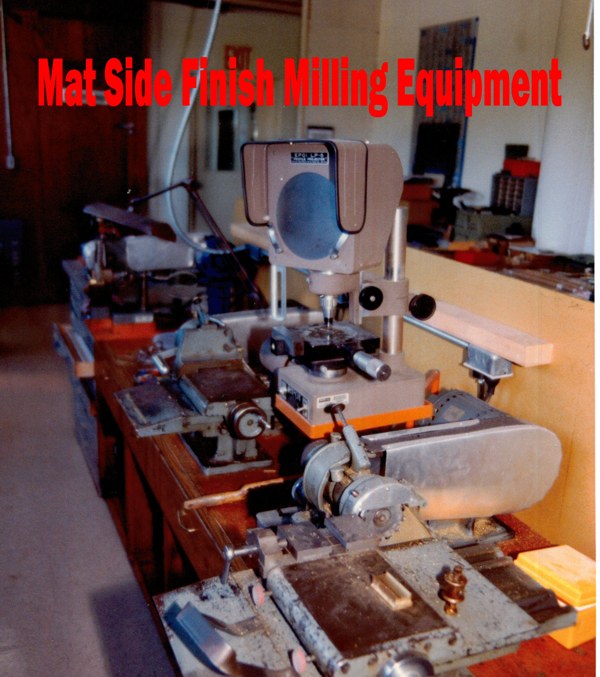

These machiens were utilized in finishing the side faces of the mat in order to smooth them and to create this correct side-bearings.

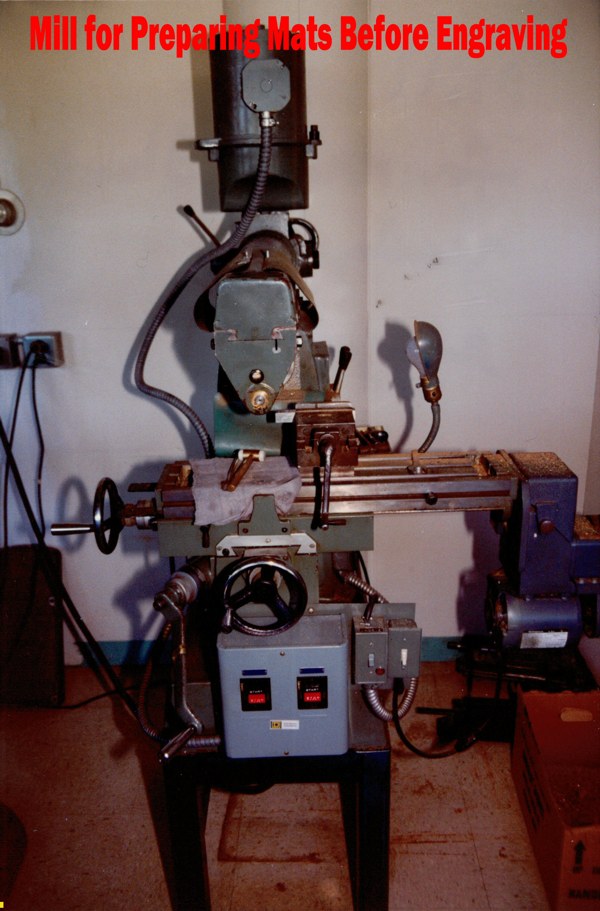

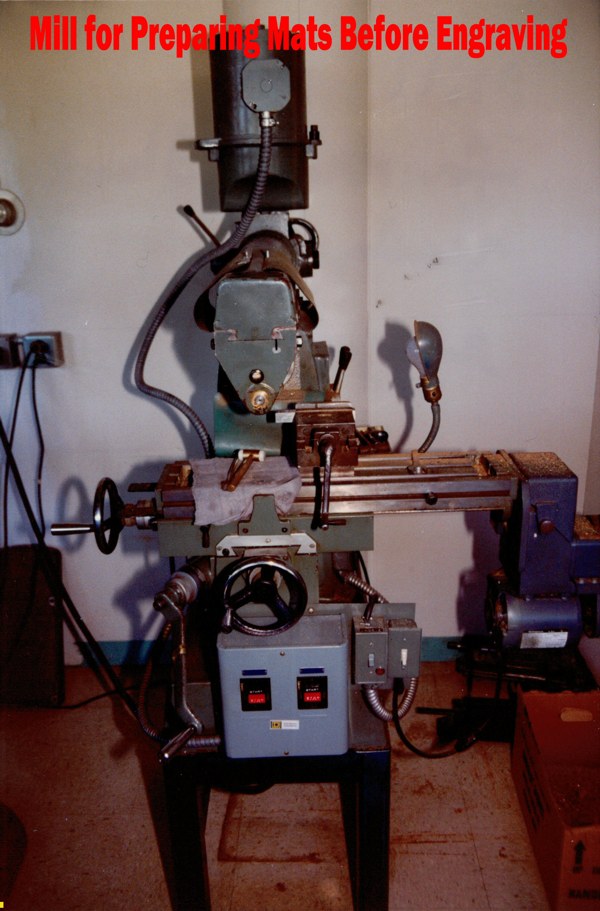

This little milling machine was capable of being changed from a vertical mill to a horizontal mill and was used to take the brass bar stock and form it into the proper format for the lino or ludlow mat bodies.

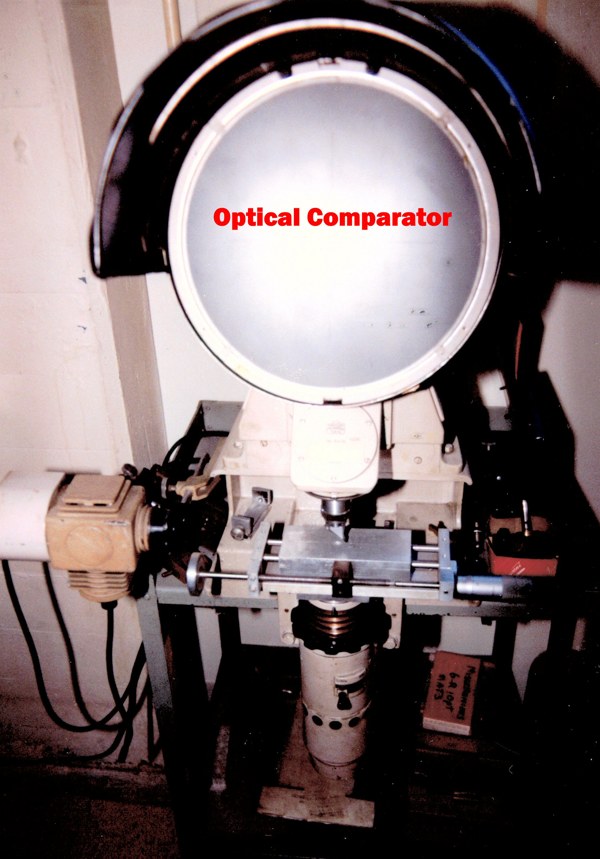

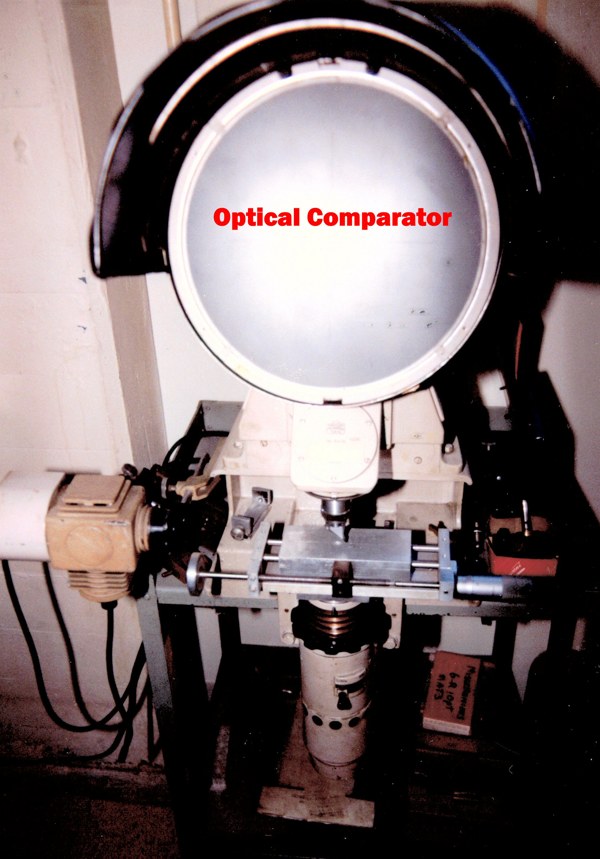

The optical comparitor was used to check for proper alignment, either using a sample from the run of mats it had to match, or using the ralative position from the edge and top of the mat body. It was also used for evaluating the cutting tool, which had to be sharpend "just so" in order to get the proper shoulder and face.

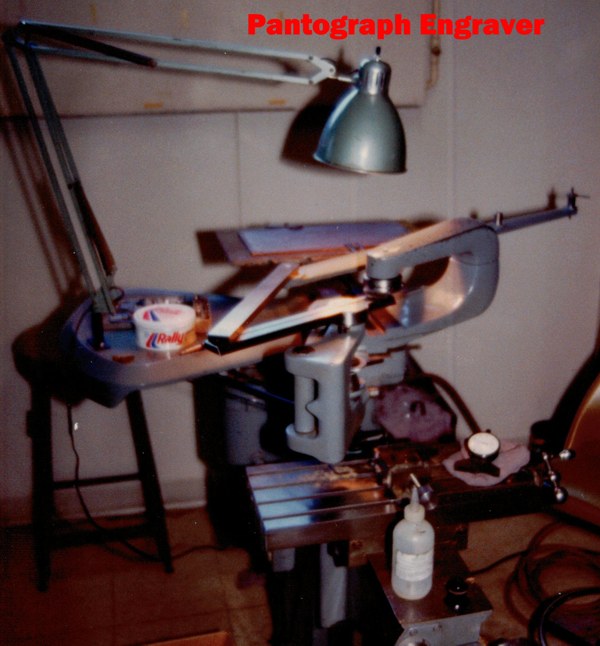

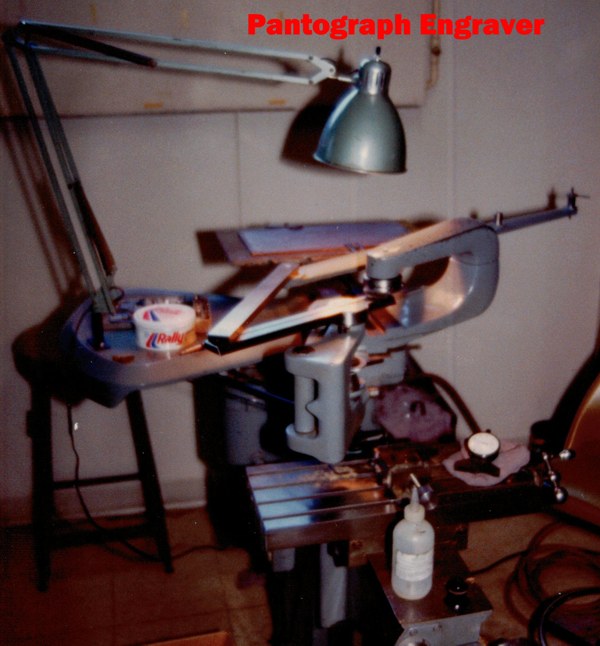

This is the pantograph engraver used for mat engraving at Kayenay. I believe most of the mats were engraved at a 50:1 reduction, meaning that the pattern plate was 50 times larger than the mat charcter being engraved. The pattern plates were photopolymer plates, and the can of car wax sitting on the machine was used to lightly lubricate the pattern plate so it didn't grab the stylus while tracing. It was important to use circular motions opposed to the spin of the cutter in order to get the cleanest floor on the engraving, which later became the actual face of the characters being cast. Of course, the last passes as you increased the depth were the most critical in that regard.

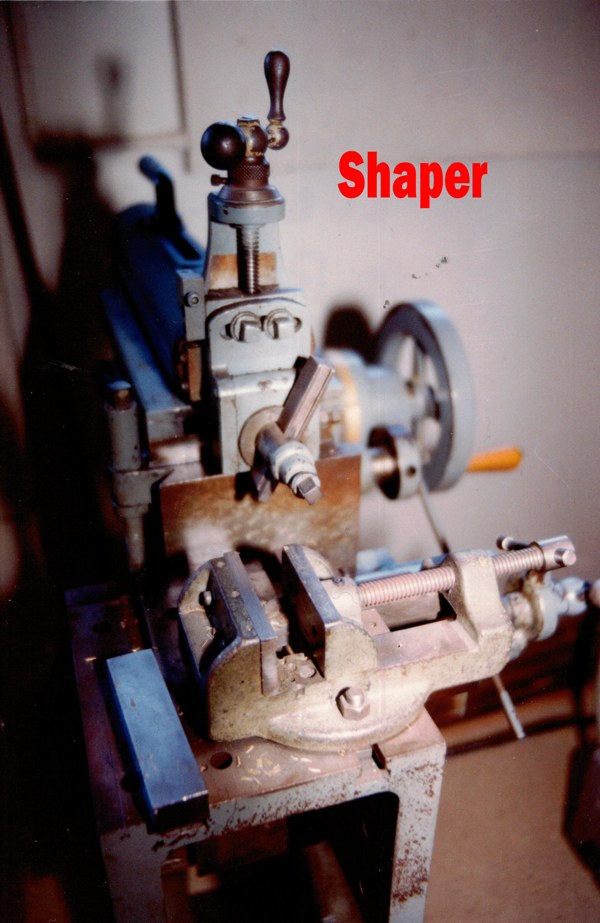

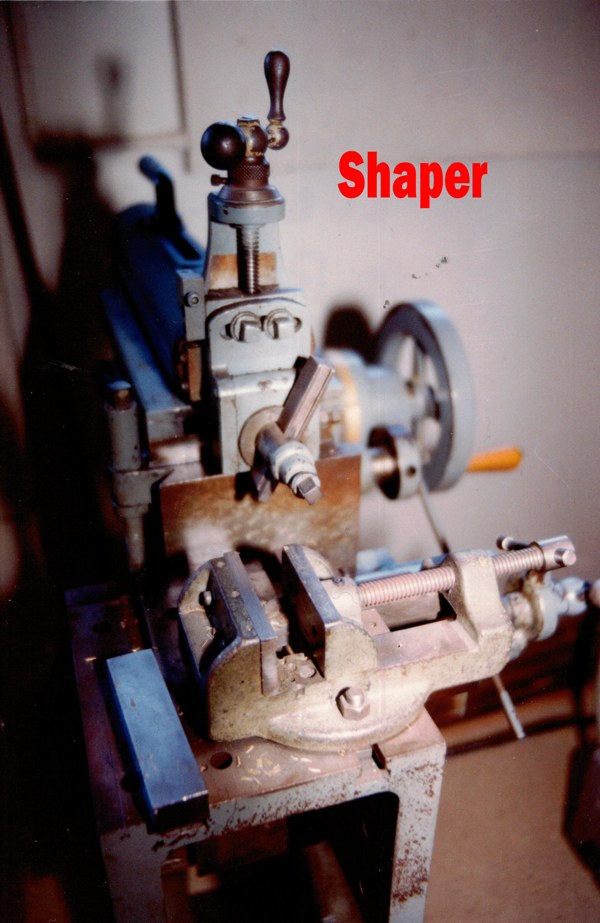

This a shaper which was used to cut border slides of rule faces. It was also used to cut the Identification and size lines on Ludlow mats where required.

This is a closer look at one of the side finishing mills. These clamped the mat on the sliding table and the side face was passed across the face of the spinning milling head They were capable of shaving off just a whisker-width to give a good finish to the side and to give the mat the proper side-berings.

I would be excited to hear from others who have engraved or stamped mats, and particularly from anyone who is hoping to develop the skills involved.

I've added John's pics to his post, they have a brief description on the pic, but I'll let John explain more fully - Admin

This was used to reduce the thickness of the matrix ears (lino) in order to run correctly thorugh the magazine. The mats were stacked in the magazine and pushed indivudually through under the cutters by moving the lever on the left.

This was the broach used to create the proper key combination on linecaster mats. The levers were raised or lowered in various combinations for the particular characters being cut at the time. The mats were put in the carriers and then pushed through the broach to cut the combinations.

These machiens were utilized in finishing the side faces of the mat in order to smooth them and to create this correct side-bearings.

This little milling machine was capable of being changed from a vertical mill to a horizontal mill and was used to take the brass bar stock and form it into the proper format for the lino or ludlow mat bodies.

The optical comparitor was used to check for proper alignment, either using a sample from the run of mats it had to match, or using the ralative position from the edge and top of the mat body. It was also used for evaluating the cutting tool, which had to be sharpend "just so" in order to get the proper shoulder and face.

This is the pantograph engraver used for mat engraving at Kayenay. I believe most of the mats were engraved at a 50:1 reduction, meaning that the pattern plate was 50 times larger than the mat charcter being engraved. The pattern plates were photopolymer plates, and the can of car wax sitting on the machine was used to lightly lubricate the pattern plate so it didn't grab the stylus while tracing. It was important to use circular motions opposed to the spin of the cutter in order to get the cleanest floor on the engraving, which later became the actual face of the characters being cast. Of course, the last passes as you increased the depth were the most critical in that regard.

This a shaper which was used to cut border slides of rule faces. It was also used to cut the Identification and size lines on Ludlow mats where required.

This is a closer look at one of the side finishing mills. These clamped the mat on the sliding table and the side face was passed across the face of the spinning milling head They were capable of shaving off just a whisker-width to give a good finish to the side and to give the mat the proper side-berings.

Posted by mikefrommontana

- February 15, 2010, 06:22:22 PMA couple notes on mat suppliers:

Woodside Press appears to be a trade typesetting house only--they're not selling mats off. At least that's how I read it.

Linecasting Machinery sells English depth of drive mats (.050 instead of U.S. .030 if I recall). Unless a machine is set up for those mats, either the slugs come out over height or they won't cast at all. English and U.S. mats cannot be mixed together.

G.T. Graphic Service and Supply http://www.gthotmetal.net/FontList.htm also sells mats along with SOS Linotype in the US, along with such collections we all might luck into.

Just because our machinery is fussy and precise is no reason it can't run for a long long time. It's up to us, that's all.

Michael Seitz

Missoula MT

Woodside Press appears to be a trade typesetting house only--they're not selling mats off. At least that's how I read it.

Linecasting Machinery sells English depth of drive mats (.050 instead of U.S. .030 if I recall). Unless a machine is set up for those mats, either the slugs come out over height or they won't cast at all. English and U.S. mats cannot be mixed together.

G.T. Graphic Service and Supply http://www.gthotmetal.net/FontList.htm also sells mats along with SOS Linotype in the US, along with such collections we all might luck into.

Just because our machinery is fussy and precise is no reason it can't run for a long long time. It's up to us, that's all.

Michael Seitz

Missoula MT

Posted by Dave Hughes

- February 15, 2010, 11:47:19 AMJust to reiterate what Mike said, Craig, it does sound like a very interesting project, which is of interest to many people here on Metal Type.

Please keep us informed on your progress. If you need any help posting photographs on the message board, you could email them to me metaltype-AT-gmail.com and I would be happy to host them and illustrate your posts.

Or you could take a look at the sharing services provided by www.photobox.com or others.

Please keep us informed on your progress. If you need any help posting photographs on the message board, you could email them to me metaltype-AT-gmail.com and I would be happy to host them and illustrate your posts.

Or you could take a look at the sharing services provided by www.photobox.com or others.

Posted by mikefrommontana

- February 14, 2010, 11:26:29 PMKeep us appraised to the results, as this sounds very interesting. Of especial curiosity will be if the face can be kept to a uniform depth. I know Ludlow resorted to engraved mats at the end of production and some folks have complained of them not having a uniform depth of drive. I suspect this is why punched mats were preferred, but the engraving likely will remove some post punching finishing.

I am also curious if the metallurgical makeup of the matrices will influence the engraving. It seems a lot of the newer mats seem to be of a very yellow (high zinc content) brass, which I suspect may not be the preferred metal for engraving. If you know somebody with a Thompson caster, it would be a good way to test the durability of the mats--though what to do with the intervening thousands of sorts might be a question.

Keep us posted. I'm going to toss this question out on the LETPRESS List and the Intertypeworld lists and see if there are any other folks with interest or knowledge applicable.

Michael Seitz

Missoula MT

I am also curious if the metallurgical makeup of the matrices will influence the engraving. It seems a lot of the newer mats seem to be of a very yellow (high zinc content) brass, which I suspect may not be the preferred metal for engraving. If you know somebody with a Thompson caster, it would be a good way to test the durability of the mats--though what to do with the intervening thousands of sorts might be a question.

Keep us posted. I'm going to toss this question out on the LETPRESS List and the Intertypeworld lists and see if there are any other folks with interest or knowledge applicable.

Michael Seitz

Missoula MT

Posted by craig_star

- February 14, 2010, 07:05:13 PMI am going to buy some flat cz120 engraving brass bar from smithsmetals. They sell it at 3/4" wide, the same as matrices and various thicknesses. I'll use their bespoke cutting service to lop it into rectangles. Then I will cut the key (pi) with a £150 new custom cutter. Then I will measure a 'a' 18pt mat and mill the new brass to these measurements.

My friends wife works in a jewelry shop which just bought a new £20000 engraving machine. I'm going to have a play with it.

My friends wife works in a jewelry shop which just bought a new £20000 engraving machine. I'm going to have a play with it.

Posted by Dan Williams

- February 14, 2010, 12:39:00 AMEconomics briefly aside, I think this is a legitimate academic question that is begging for answers. Sorry I dont have the info. But it seems that more than a few people are possibly interested (Craig, Mike, and yes me) and John Henry probably has the best insight to the process. Here is what I suggest, and I am totally honest. Someone should be encouraged to research this as part of their high school or college project. They would get expert advise (under a professor or advisor) would get access to information and people that others would not, and would have the available time. They could publish or post what they find, get bread-and-butter transcript credit and everyone could benefit. A patent search could be a start, and then interviews with folks like John Henry. You know, Mergenthaler was making mats into the 70s. Bet there are hundreds of people who made mats now enjoying retirement or 2nd careers. They wouldnt know or necessarily care that anyone is asking these questions. But if some kids call with questions.... Boy, I hope someone takes up the challenge.

Posted by mikefrommontana

- February 11, 2010, 09:32:00 PMMy interest in mat fabrication is probably more an intellectual excercise, but still the information should be retained somewhere, just in case somebody wants to make mats in the future. I've an idea how it could be done, but what order of operations was required for making the mats and punches is useful knowledge that would save reinventing the wheel.

A lot of machinery is going to vanish in the next generation. I would place where we are now to where steam locomotives in the US were in the mid-1950s. Compare that to what's running today and it's pretty mind boggling. I suppose it's not our problem, but it's a shame for such a bridge technology to vanish from our knowledge. If you don't believe that, start finding people who still have a decent skill set doing cold type and negative stripping.

So, again, does anybody know, or know where to look, for information on matrice manufacturing? Likewise, does anybody have any fabrication equipment/punches/whatall remaining?

Michael Seitz

Missoula MT

A lot of machinery is going to vanish in the next generation. I would place where we are now to where steam locomotives in the US were in the mid-1950s. Compare that to what's running today and it's pretty mind boggling. I suppose it's not our problem, but it's a shame for such a bridge technology to vanish from our knowledge. If you don't believe that, start finding people who still have a decent skill set doing cold type and negative stripping.

So, again, does anybody know, or know where to look, for information on matrice manufacturing? Likewise, does anybody have any fabrication equipment/punches/whatall remaining?

Michael Seitz

Missoula MT

Posted by Dan Williams

- February 08, 2010, 04:25:58 AMI still see mat sales on ebay. Good question about completeness of fonts and certainly the condition of fonts, also. During the letterpress era, every magazine of mats had a companion set of pi mats in a cabinet, somewhere.

Regarding availability, there seem to be various sources of used mats. Don Black, and SOS Lino are some names that come to mind and there are certainly many others. The idea of allied users is a good one; these forums help provide that service.

The last trained users of the technology arent that old - perhaps into their late 60s. Many of these fellows socked away machines and mats in their garages. I have seen and inspected estates that seem to bear that out.

There will be more of these sales that surface.

In my opinion, the greatest obstacle to preserving the stocks of machines and parts has been the low perceived value of the equipment relative to scrap value. Frankly, you couldnt give the stuff away not ten years ago. Some time ago a collector asked why he should pay for my model 35 when he could get it free somewhere else. So I so let it go to scrap when the estate property sold 5 years ago. On the other hand, for nice price I sold a model 29 to a collector on the West Coast.

So I think that when folks are willing to spend money for parts and service, it will go along way to ensure availability of these things.

Regarding availability, there seem to be various sources of used mats. Don Black, and SOS Lino are some names that come to mind and there are certainly many others. The idea of allied users is a good one; these forums help provide that service.

The last trained users of the technology arent that old - perhaps into their late 60s. Many of these fellows socked away machines and mats in their garages. I have seen and inspected estates that seem to bear that out.

There will be more of these sales that surface.

In my opinion, the greatest obstacle to preserving the stocks of machines and parts has been the low perceived value of the equipment relative to scrap value. Frankly, you couldnt give the stuff away not ten years ago. Some time ago a collector asked why he should pay for my model 35 when he could get it free somewhere else. So I so let it go to scrap when the estate property sold 5 years ago. On the other hand, for nice price I sold a model 29 to a collector on the West Coast.

So I think that when folks are willing to spend money for parts and service, it will go along way to ensure availability of these things.

Posted by mikefrommontana

- February 07, 2010, 03:41:27 AMI think we, as the linecasting community, really need to look at making mats and to have that knowledge (and preferably machinery) in place for the future. All these wonderful machines are handicapped by the need for mats. Each font of mats is handicapped by either general wear (hairlining) or failure of critical sorts.

How many of you have gotten mats and found that there were no lower case e's or r's or periods? Ebay is not a source for mats, period. There was a year long period that there were mats, but that was one operator, and given the price of scrap, the likelihood of that happening again is rather slim. I know that there are places where mats are seemingly common, but to think that will last another 10 or 15 years is wishful thinking.

If we want to keep these machines going, just as people keep running (and building from scratch sometimes!) steam tractors, then we need to a: find a new generation of people who consider these machines important and worth preserving, and b: maintain parts and mat availablity (just having drawings out in public view would help).

Perhaps we need to develop a central clearinghouse for those who want to retire out so that their equipment/mats/parts would be available to newcomers, and not just shuffled off to the scrap heap as is mostly the case now. I will give immense kudos to Larry Raid and his Linotype University in Iowa, but we need more than just his efforts to carry the day. A major U.S. parts jobber and one of the few remaining traveling mechanics are getting up in years and soon will be gone. Who will replace them? It's quite frankly up to us to do something--else we might as well scrap out everything now.

So, if somebody does know the production process for making mats, it would be most useful to post that information, or provide reference to publications or whereever that information is. This is a great discussion and I hope others post to it.

How many of you have gotten mats and found that there were no lower case e's or r's or periods? Ebay is not a source for mats, period. There was a year long period that there were mats, but that was one operator, and given the price of scrap, the likelihood of that happening again is rather slim. I know that there are places where mats are seemingly common, but to think that will last another 10 or 15 years is wishful thinking.

If we want to keep these machines going, just as people keep running (and building from scratch sometimes!) steam tractors, then we need to a: find a new generation of people who consider these machines important and worth preserving, and b: maintain parts and mat availablity (just having drawings out in public view would help).

Perhaps we need to develop a central clearinghouse for those who want to retire out so that their equipment/mats/parts would be available to newcomers, and not just shuffled off to the scrap heap as is mostly the case now. I will give immense kudos to Larry Raid and his Linotype University in Iowa, but we need more than just his efforts to carry the day. A major U.S. parts jobber and one of the few remaining traveling mechanics are getting up in years and soon will be gone. Who will replace them? It's quite frankly up to us to do something--else we might as well scrap out everything now.

So, if somebody does know the production process for making mats, it would be most useful to post that information, or provide reference to publications or whereever that information is. This is a great discussion and I hope others post to it.

Posted by craig_star

- February 05, 2010, 09:05:55 AMHi Guys,

Thanks for all this great advice.

Dave: those pics at Intertype 1966 are great. Those pantographs are huge! I wonder what modern pantograph could be used today?

Dan: yes there is a small problem with the distributer. I have tried earnestly to sort it out to no avail. The mats, particularly the vowels get stuck in the copper fins and dont fall in the magazine. If they pile up on top of one another the the one that protrudes out of the top causes the crash. Ive tried everything. If I tweak it I make it worse. Its really annoying, I have to always check the coast is clear after I send a line away so then im ok to do another. Something is out of alignment, but only slightly.

Other than that the machine is perfect.

Mechanic & jhenry: thanks for the links.

I have the project on hold until I learn a little more. I am in talks with local engineers. I might have a go just for the fun of it. One question I think; CNC the character in the mat or make punches? or even pantograph?

Thanks for all this great advice.

Dave: those pics at Intertype 1966 are great. Those pantographs are huge! I wonder what modern pantograph could be used today?

Dan: yes there is a small problem with the distributer. I have tried earnestly to sort it out to no avail. The mats, particularly the vowels get stuck in the copper fins and dont fall in the magazine. If they pile up on top of one another the the one that protrudes out of the top causes the crash. Ive tried everything. If I tweak it I make it worse. Its really annoying, I have to always check the coast is clear after I send a line away so then im ok to do another. Something is out of alignment, but only slightly.

Other than that the machine is perfect.

Mechanic & jhenry: thanks for the links.

I have the project on hold until I learn a little more. I am in talks with local engineers. I might have a go just for the fun of it. One question I think; CNC the character in the mat or make punches? or even pantograph?

Posted by parallel_imp

- February 03, 2010, 04:55:36 PMThe machine I've seen to cut matrix teeth OFF is indeed small. Great when you have a pi mat (that is, one with all the teeth ) that you want to run in a particular channel, or a mat that you want to run pi (that'd be one with no teeth). Removing teeth is easy enough to do with a file. But there isn't an easy way to add teeth, is there?

I have a mat that had a dovetail cut into it and an engraved logo piece sweated into it, rather like a border slide placed in the slide block. That is an alternative to engraving directly on a matrix.

I have a mat that had a dovetail cut into it and an engraved logo piece sweated into it, rather like a border slide placed in the slide block. That is an alternative to engraving directly on a matrix.

Posted by Mechanic

- February 02, 2010, 10:49:38 PMIf you haven't already run across it, the following url will take you to a review of "Anatomy of a typeface" by Alexander S. Lawson. It maybe of interest to you.

http://tinyurl.com/yjtlp6c

Canadian Linotype did some matrix modification. The fact that Canada has a large French population they often had to produce special accent characters and cut the teeth to run in selected magazine channels. If my memory is correct the machine use to cut the teeth was not that large. However I did not work in that section.

http://tinyurl.com/yjtlp6c

Canadian Linotype did some matrix modification. The fact that Canada has a large French population they often had to produce special accent characters and cut the teeth to run in selected magazine channels. If my memory is correct the machine use to cut the teeth was not that large. However I did not work in that section.

Posted by jhenry

- January 31, 2010, 04:35:26 PMCraig:

There were a couple companies in the US making special character mats by using Gorton Pantograph engraving machines which would reduce the image from a etched pattern plate (we used photopolymer pattern plates) it would take at least five to ten minutes to engrave a suitable mat, and the most critical part of the process was the sharpening of the engraving tool which had to be only a couple thousandths of an inch at the tip in order to get sharp corners in the characters. I have always thought it would be possible to drive the pattern arm of the pantograph with a CNC device which need not have the resolution to engrave an 8pt. character, but would be able to swing a pattern 20 times larger, and use the pantograph to do the actual cutting. Speed and uniformity of the cut is critical, and the CNC device could be programmed to do the work with greater facility than a human hand.

No pattern plates would be necessary, and any image could be produced.

We purchased a complete matrix engraving shop in Northern Wisconsin, and ran it for a short period of time. It became evident during that time that the costs associated with the labor involved made it not feasible commercially. However, there is much more interest today than 15 years ago, and with CNC, it might be possible to make a profit. The equipment included some equipment from the Ludlow shops in Chicago and a monster combination cutter from Linotype.

By the way, there seemed to be more interest in Monotype display mats for borders and special characters than Linecaster mats, but we did some engraving of accents and logotype mats (for better fitting), and Ludlow mats for special characters.

John G. Henry

There were a couple companies in the US making special character mats by using Gorton Pantograph engraving machines which would reduce the image from a etched pattern plate (we used photopolymer pattern plates) it would take at least five to ten minutes to engrave a suitable mat, and the most critical part of the process was the sharpening of the engraving tool which had to be only a couple thousandths of an inch at the tip in order to get sharp corners in the characters. I have always thought it would be possible to drive the pattern arm of the pantograph with a CNC device which need not have the resolution to engrave an 8pt. character, but would be able to swing a pattern 20 times larger, and use the pantograph to do the actual cutting. Speed and uniformity of the cut is critical, and the CNC device could be programmed to do the work with greater facility than a human hand.

No pattern plates would be necessary, and any image could be produced.

We purchased a complete matrix engraving shop in Northern Wisconsin, and ran it for a short period of time. It became evident during that time that the costs associated with the labor involved made it not feasible commercially. However, there is much more interest today than 15 years ago, and with CNC, it might be possible to make a profit. The equipment included some equipment from the Ludlow shops in Chicago and a monster combination cutter from Linotype.

By the way, there seemed to be more interest in Monotype display mats for borders and special characters than Linecaster mats, but we did some engraving of accents and logotype mats (for better fitting), and Ludlow mats for special characters.

John G. Henry

Posted by Mechanic

- January 31, 2010, 02:32:31 AMFollowing is a site I had forgoten about. The site contains a lot scanned books related to maintenance of linotypes including Linotype Machine Principles. These files can all be downloaded:-

http://www.linotype.org/onlinedocs.html

http://www.linotype.org/onlinedocs.html

Printers' Tales - Over 30 stories from the pre-digital age. Buy now on Amazon/Apple Books

☛ Don't miss our illustrated newsletters. Click here to see examples and subscribe. ☚