Category: Historical

Historical items

Christophe Plantin Print Shop

Many thanks to Mike Topper for sending in these pictures he took at the Christophe Plantin Museum in Antwerp.

British Print Trade Union Cards 1946-1993

From the late Dave Bowles’ collection of London Fleet Street compositors items comes this great collection of trade union membership cards from 1946 right through to the 1990s.

We have another page of union membership cards, covering the period 1924-1945 here: British Print Trade Union Cards 1924-1945.

Linotype Model 1

Compugraphic Universal 2

Intertype Fotosetter

It is an early photosetter that used mainly linecaster technology to produce photoset output.

Interested in early photosetting technology? Check out the Early Photosetting Chat section of the Forum.

Linotype Linocomp 1

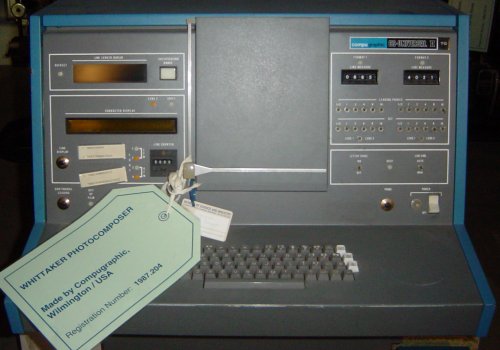

Whittaker S.A.M.

Intertype Monarch

The Intertype Monarch was designed without a manual keyboard. It relied totally on Teletypesetting (TTS) for setting type, using instructions from perforated tape.

It had an output of 14 lines per minute. A suction manifold held the matrices to the delivery belt as they were delivered at high speed to the assembler.