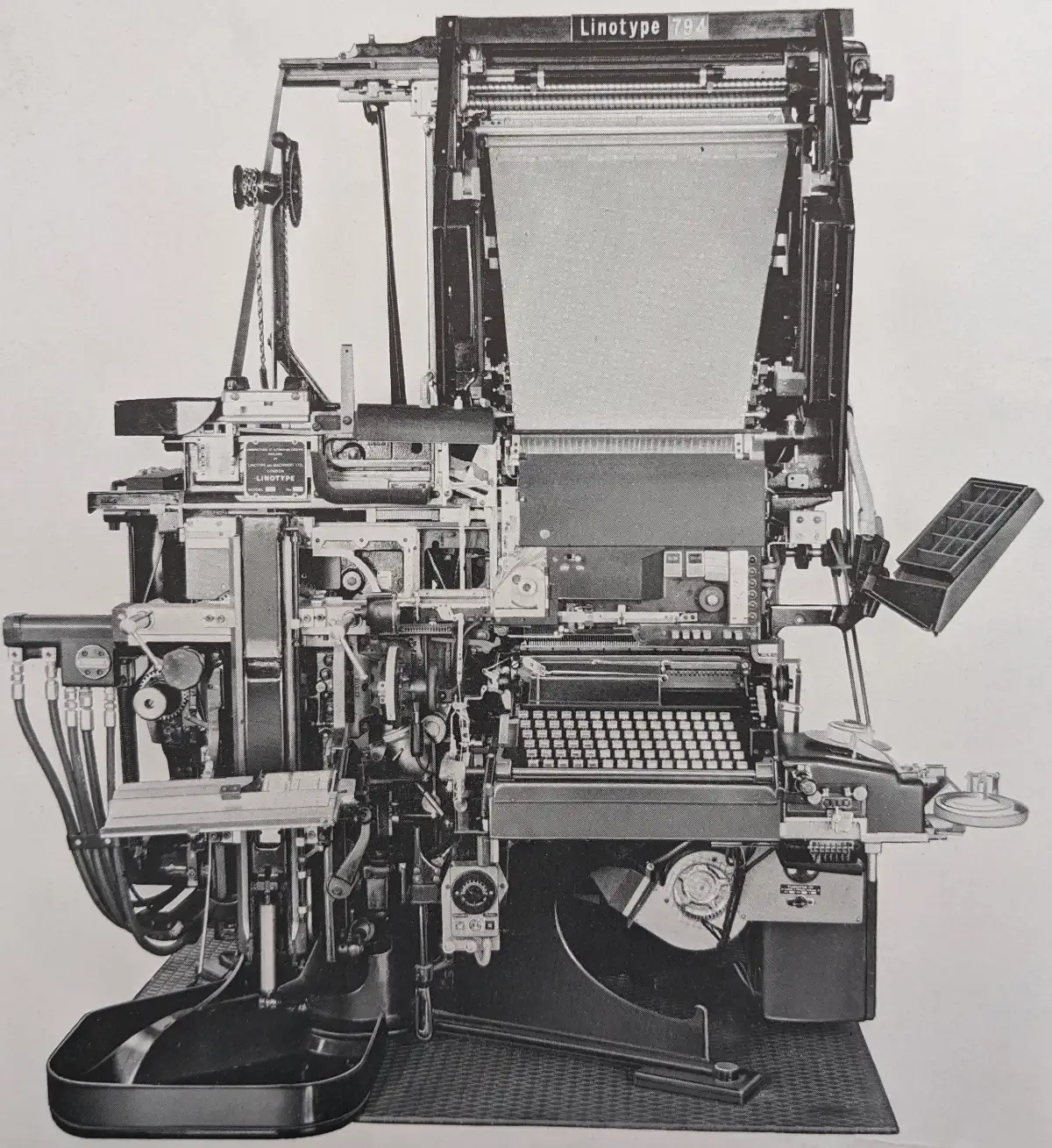

The ‘794’ has been designed to meet the particular requirements of large newspaper offices. It will become the standard all-purpose ‘Linotype’ for three very good reasons.

Reliability

Yesterday’s Technology . . . Today!

The ‘794’ has been designed to meet the particular requirements of large newspaper offices. It will become the standard all-purpose ‘Linotype’ for three very good reasons.

Reliability

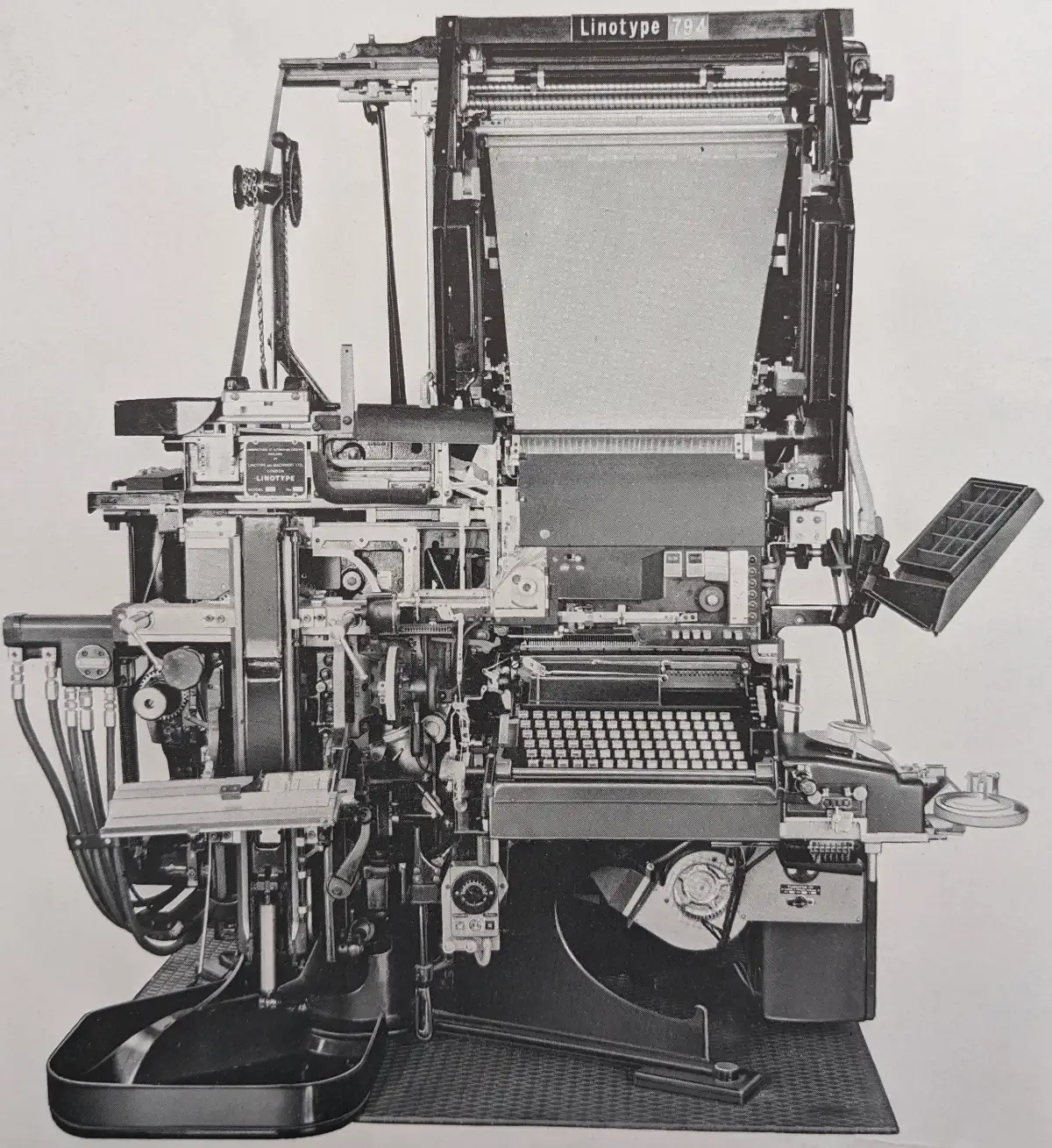

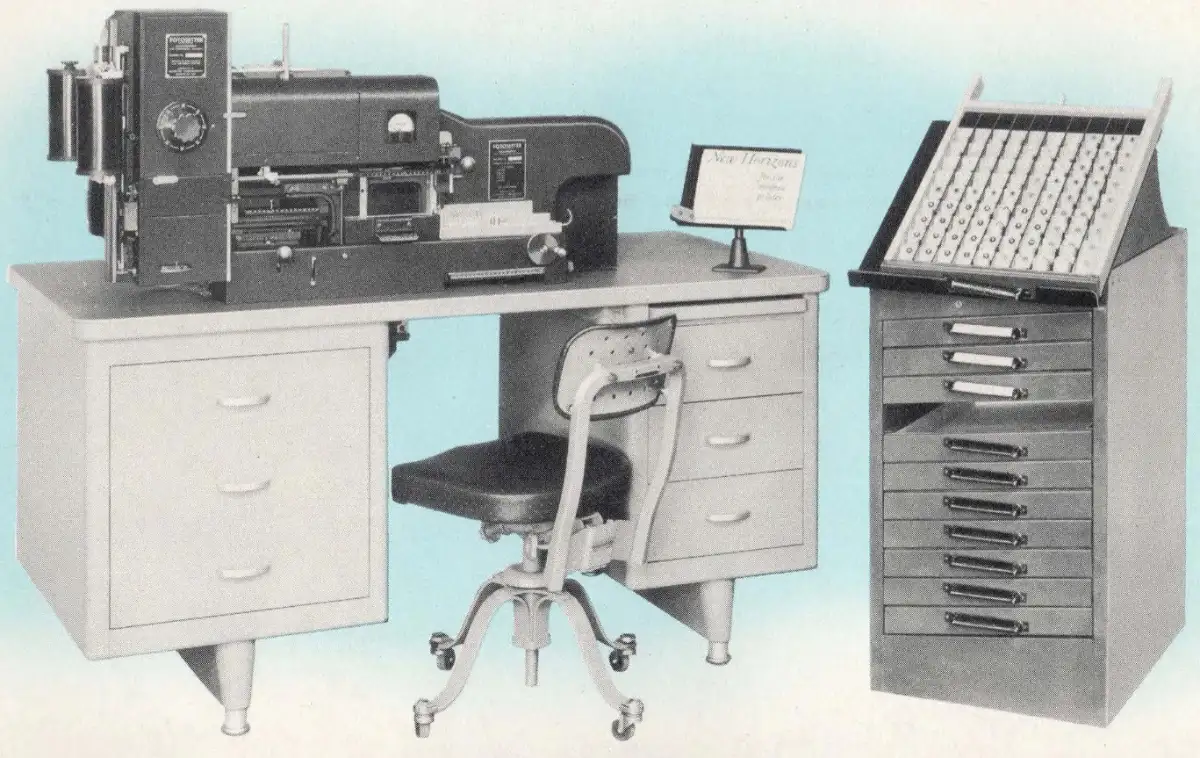

This machine was intended to produce display lines of type, such as newspaper headlines, as a Ludlow Typograph set-up would have done in a hot metal shop.

It was also suggested in the publicity material that it would also be useful for setting languages such as Chinese and Japanese, where the number of characters used was greater than the number of keys on the Intertype Fotosetter.

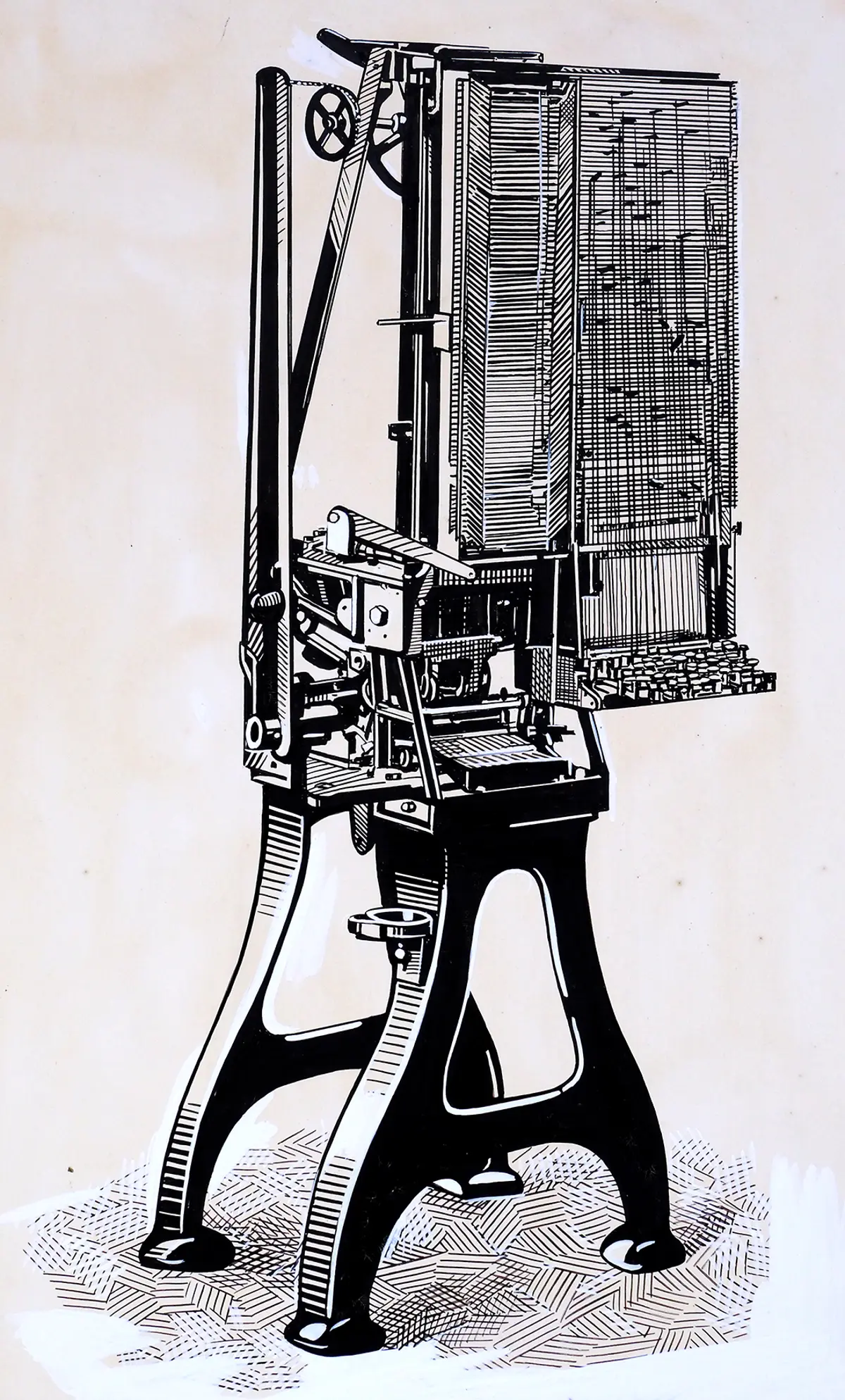

The illustrations on this page are from the Ottmar Mergenthaler Museum, digitised by Doug Wilson.

You can read more about how Doug came across these images on the Metal Type forum here: Linotype: The Book.

Many thanks to Rocky Baranowski, from Arizona USA, for sending in these pictures from his collection.

These gifts would have been given away at trade shows and exhibitions early in the 20th Century.

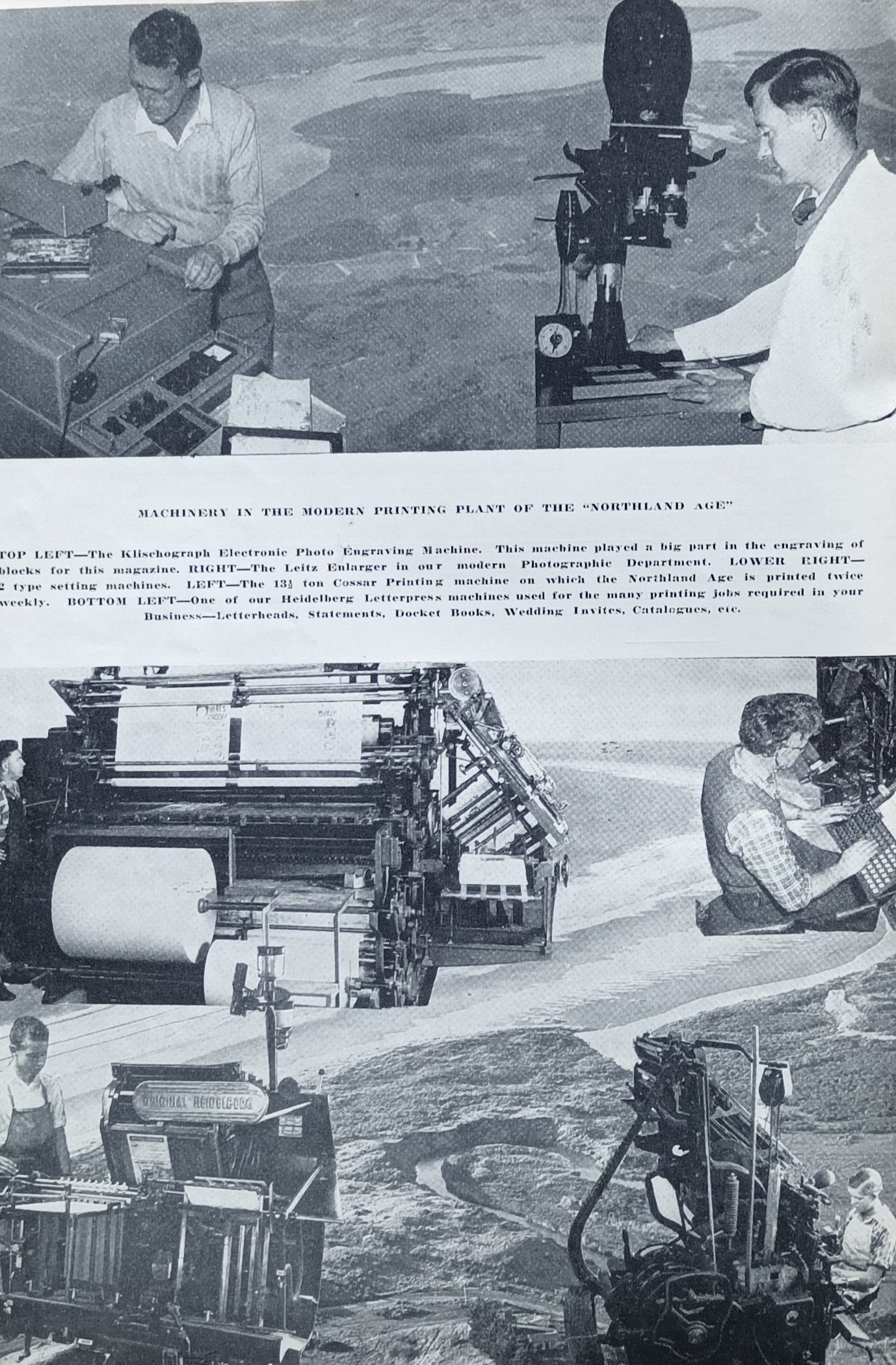

Many thanks to Graeme How, from New Zealand for sending in this illustrated article.

Machinery In The Modern Printing Plant of the ‘Northland Age’ –

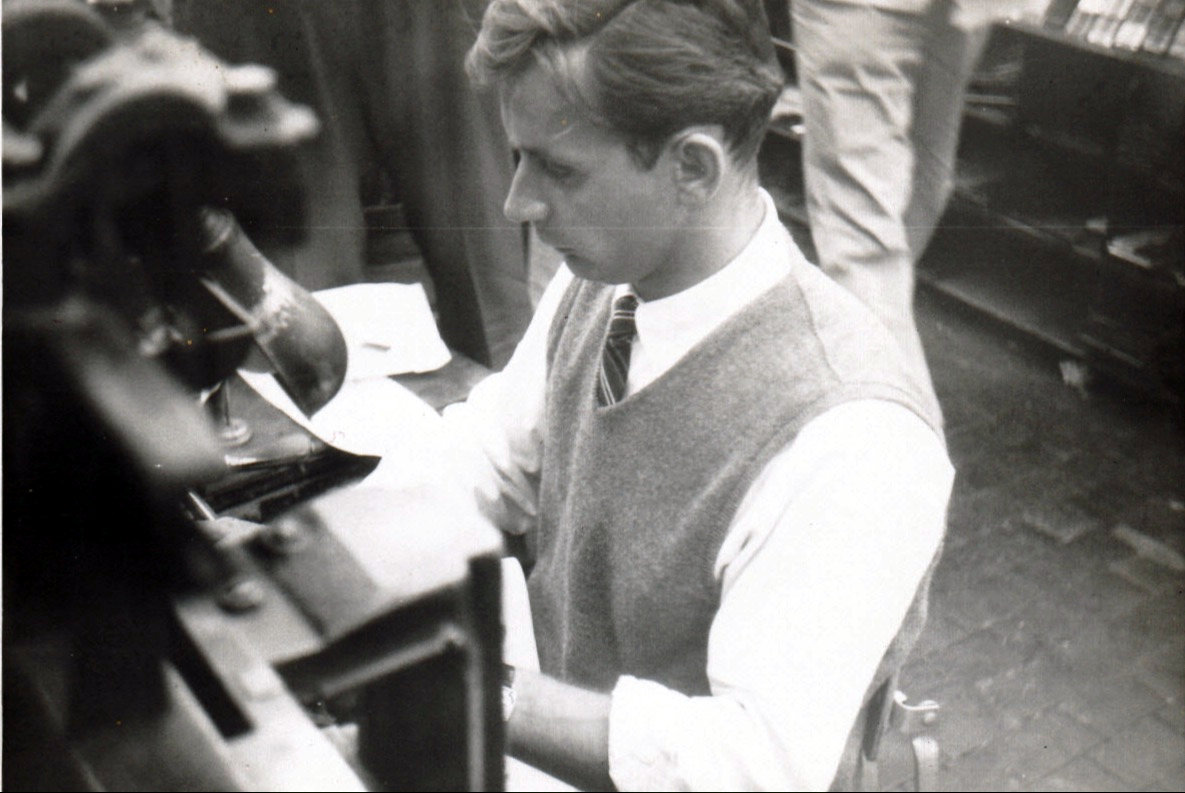

Many thanks to Bill Westland for sending in these great photographs. They were taken at the Rochester Times-Union and Rochester Democrat and Chronicle newspapers before computerisation.

A well-dressed Linotype operator

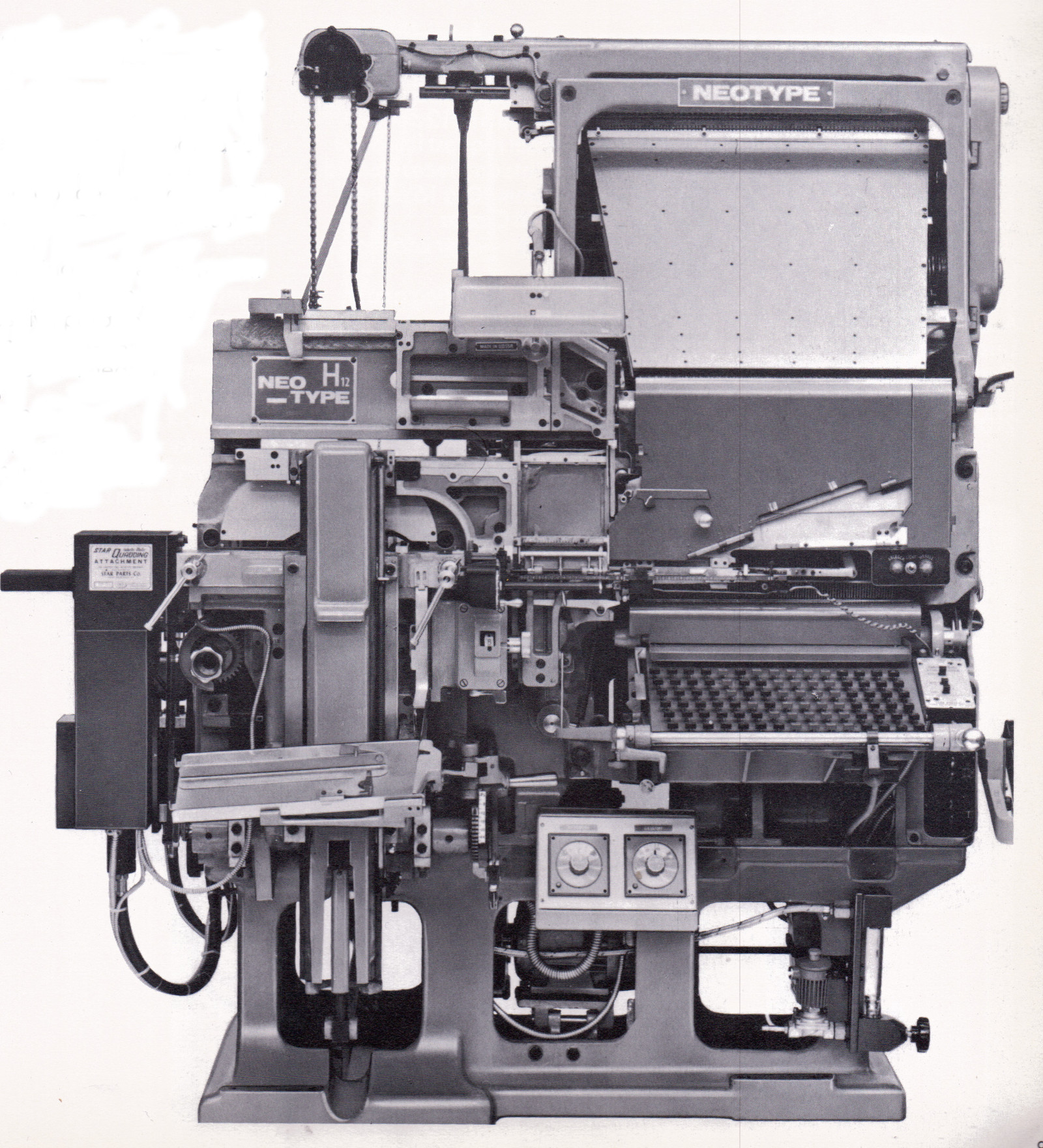

Check the “Related Pages” menu for details and pictures of Neotype linecasters.

Information about Russian linecasting machines is pretty scarce on the internet, but the Metal Type Forum has some real gems.

Check the “Related Pages” menu for further reading on Russian linecasters.

The following pictures and descriptions come from an un-dated glossy brochure produced by Neotype, West Germany.

There is some lively discussion about these machines on the Forum.

There are even pictures of some of these machines “in the wild.”