The illustrations on this page are from the Ottmar Mergenthaler Museum, digitised by Doug Wilson.

You can read more about how Doug came across these images on the Metal Type forum here: Linotype: The Book.

Yesterday’s Technology . . . Today!

The illustrations on this page are from the Ottmar Mergenthaler Museum, digitised by Doug Wilson.

You can read more about how Doug came across these images on the Metal Type forum here: Linotype: The Book.

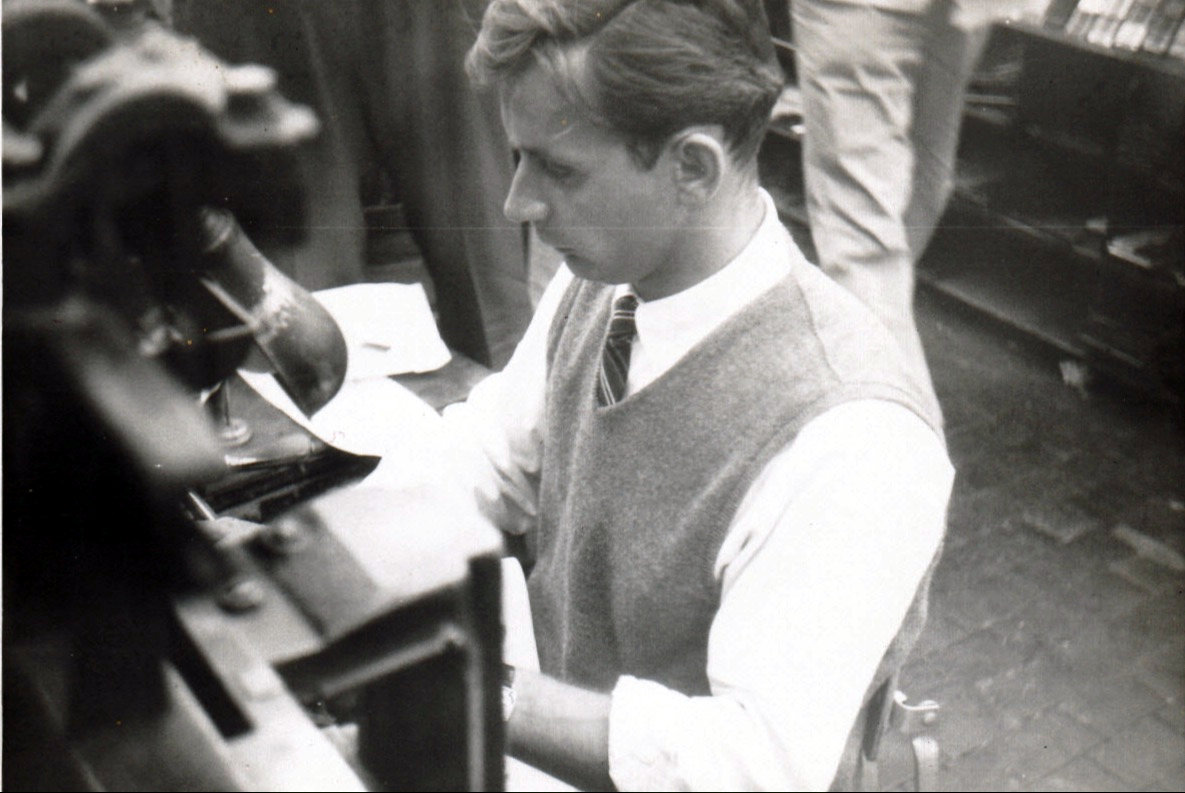

Many thanks to Bill Westland for sending in these great photographs. They were taken at the Rochester Times-Union and Rochester Democrat and Chronicle newspapers before computerisation.

A well-dressed Linotype operator

The date is Sunday, July 2, 1978, the last time that the New York Times was printed using hot metal.

David Loeb Weiss, then a proofreader and Carl Schlesinger a Linotype operator filmed and narrated this film to record the occasion.

Part of Metal Type’s Printing Advice section, here Phil discusses the long-lost art of paper ruling.

PAPER RULING was my Dad’s first trade. He apprenticed to this at the age of 14 and worked a good part of his life doing this. Dad eventually had to get into printing as it turned out to be impossible to earn a living in small town Regina doing paper ruling only.

An anecdote sent in by Bob Turner.

BACK IN MY DAY as a typesetter, among other things, the first rule of typesetting was to “follow copy” – even if somebody threw it out the window.

The sixth in a series of stories sent in by Greg Fischer (aka Linofish).

Says Greg: “All the incidents happened at the Trenton NJ Trentonian, between 1958 and 1965. This was at the old Front Street building. In 1965, we moved to a brand new plant with a new Hoe Colormatic letterpress. Much improved from the old building which was said to be used at one time by the Mercer Automoble Company.

The fifth a series of stories sent in by Greg Fischer (aka Linofish).

Says Greg: “All the incidents happened at the Trenton NJ Trentonian, between 1958 and 1965. This was at the old Front Street building. In 1965, we moved to a brand new plant with a new Hoe Colormatic letterpress. Much improved from the old building which was said to be used at one time by the Mercer Automoble Company.

The fourth a series of stories sent in by Greg Fischer (aka Linofish).

Says Greg: “All the incidents happened at the Trenton NJ Trentonian, between 1958 and 1965. This was at the old Front Street building. In 1965, we moved to a brand new plant with a new Hoe Colormatic letterpress. Much improved from the old building which was said to be used at one time by the Mercer Automoble Company.

The third in a series of stories sent in by Greg Fischer (aka Linofish).

Says Greg: “All the incidents happened at the Trenton NJ Trentonian, between 1958 and 1965. This was at the old Front Street building. In 1965, we moved to a brand new plant with a new Hoe Colormatic letterpress. Much improved from the old building which was said to be used at one time by the Mercer Automoble Company.

The second in a series of stories sent in by Greg Fischer (aka Linofish).

Says Greg: “All the incidents happened at the Trenton NJ Trentonian, between 1958 and 1965. This was at the old Front Street building. In 1965, we moved to a brand new plant with a new Hoe Colormatic letterpress. Much improved from the old building which was said to be used at one time by the Mercer Automoble Company.