Category: Composition

Linotype Model 8 Video

Many thanks to the Provost News, Provost, Alberta, Canada, for allowing Metal Type to make use of this video.

The machine has quite a history after having been saved from “The Great Fire of Provost” in 1946.

Linotype Model 31 Video

Robert Griffith sent in this video of a Linotype Model 31.

The footage was shot in October 2005 at the Museum of Printing History, Houston, Texas, USA.

Model K Elrod Restoration

Thanks largely to John Nicholson of Hamilton, NZ, the Model K Elrod which had been in storage at the Taranaki Aviation Transport And Technology Museum (TATATM), New Plymouth, is now operational.

To the writer’s knowledge, the Model K had been in the lean-to store of the museum, on a heavy wooden plank base since its arrival at the museum and never used since de-commissioning at the donor’s premises (Taranaki Newspapers Ltd., New Plymouth) around 1985.

The Modern Typograph

The fascinating story of how a new version of this old machine came to be manufactured in 1960.

Article taken from The History of the Printer by Dr. James Eckman, published in 1965 by North American Publishing Company, Philadelphia, USA.

July 3, 1886

Many thanks to the Rutgers University Libraries, John Depol Collection for permission to use this picture.

On July 3, 1886, seated at the keyboard of his new machine, Ottmar Mergenthaler handed to Whitelaw Reid a slug of metal. Reid exclaimed, “It’s a line-of-type!” Thus was christened the forerunner of today’s modern linecasting machine: the Linotype.

All-Purpose Linotype

Details of the APL (Linotype’s version of the Ludlow) taken from “Linotype Machine Principles” published in 1940.

THE ALL-PURPOSE LINOTYPE (APL) is a complete, self-contained unit for the casting of type in the form of slugs, in faces ranging from 6 point to 144 point; for casting of furniture, rules, borders, decorative and spacing material from 6 to 72 point body, and 42 picas in length.

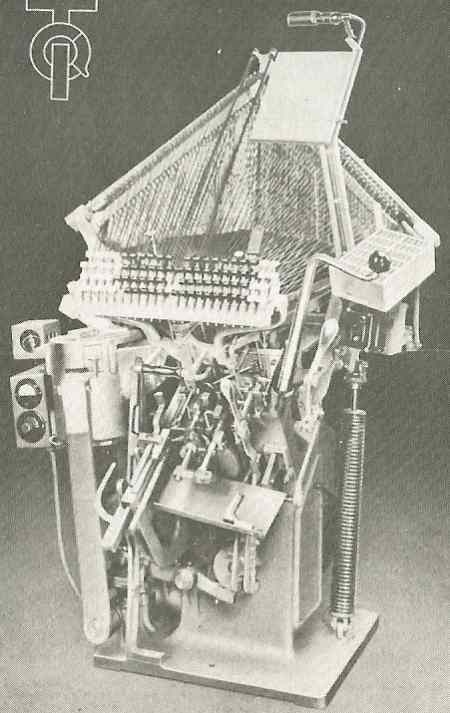

Anatomy of a Linotype

Assembly

FEATURES of the Linotype Assembly Mechanism taken from “Linotype Leadership” published in 1930 by the Mergenthaler Linotype Company.

1 – Swinging Keyboard

2 – Removable Keyboard cams

3 – Single Power-Driven Keyboard

4 – Keyboard Lock

5 – Escapement

6 – Die-Cut Cams and One-Piece Yoke

7 – Keyboard Rubber Roll

8 – Complete Bank of Key Bars Removable as a Unit

9 – Assembler Front

10 – Assembler Entrance Cover

11 – Geared Assembler Drive

12 – Offset Assembling Elevator

13 – Endless Matrix Delivery Belt

14 – Assembler with Quick-Removable Star Wheel

15 – Rapid Change of Measure

16 – Line Delivery Carriage

17 – Assembler Slide Roller Bearing

18 – Assembling Elevator

19 – Adjustable Spaceband Key

20 – Linotype Spaceband and Slide

21 – Four Thicknesses of Spacebands

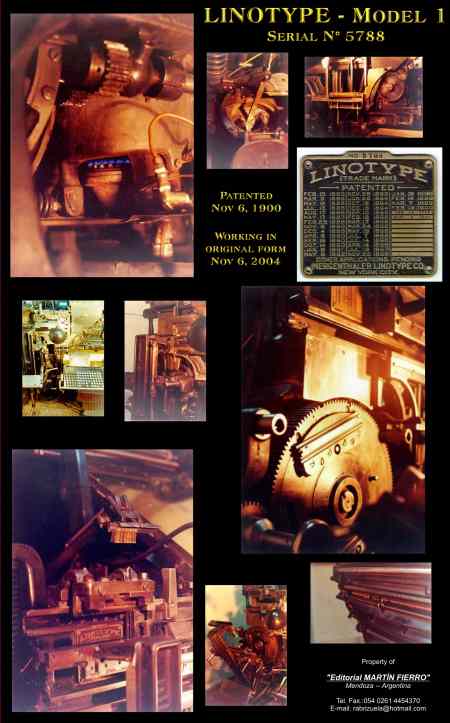

Linotype Model 1 For Sale

Ruben Brizuela, from Argentina, sent in this excellent graphic of a Model 1 Linotype, serial No. 5788, in full working order, that he would like to sell.

I’m not sure how rare the Model 1 is, but judging by the graphic the machine looks in good condition and worth preserving.

Peter Ainsworth, Monotype Caster

Peter Ainsworth sent in these photos, the man at the Monotype Caster is Peter. The photos come from a Mouldtype brochure.

Monotype fan? Don’t miss the Monotype Chat section of the Metal Type Forum.