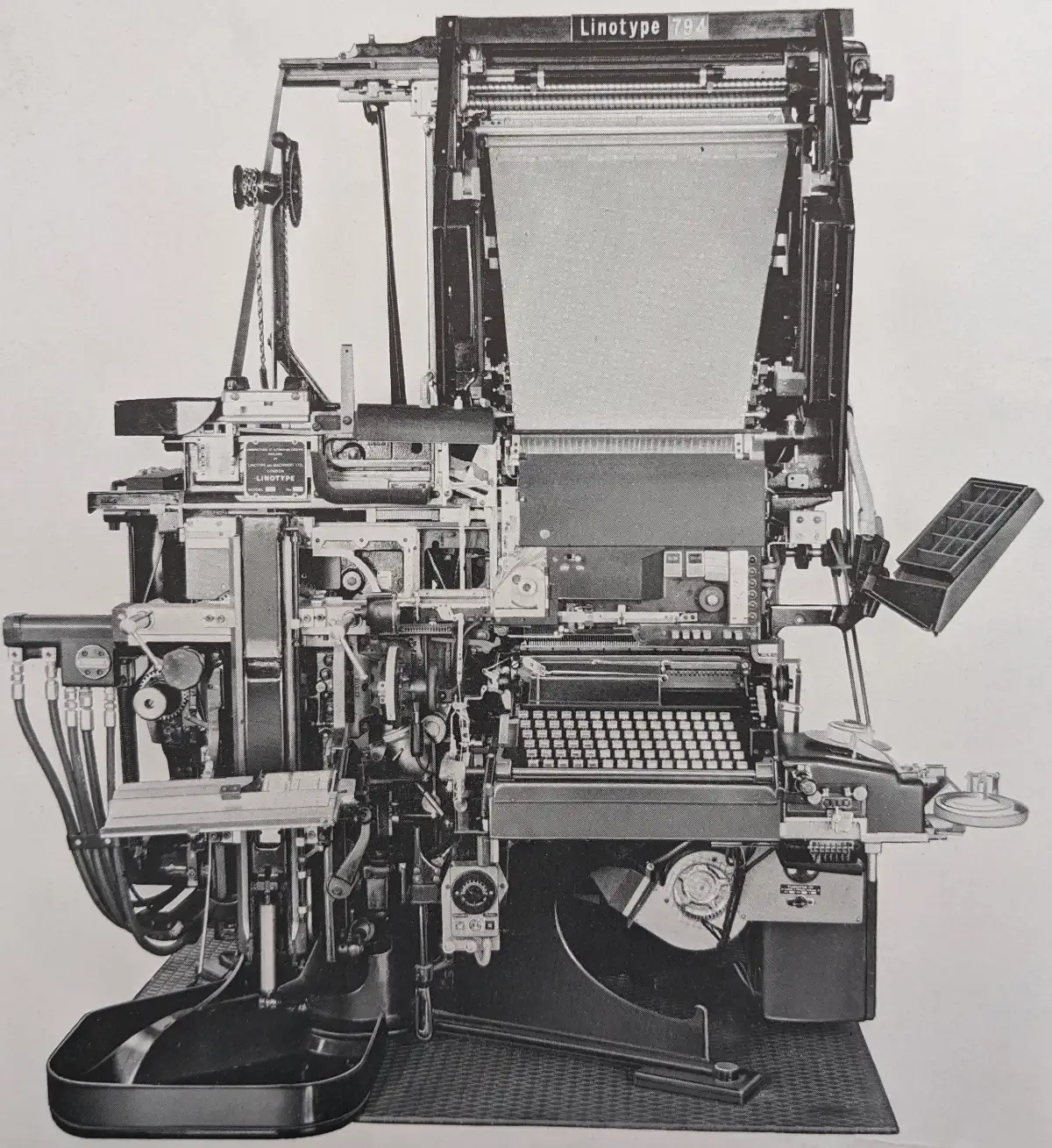

The ‘794’ has been designed to meet the particular requirements of large newspaper offices. It will become the standard all-purpose ‘Linotype’ for three very good reasons.

Reliability

Ease of operation

Simplicity of maintenance

These are the factors that all composing room managers look for in their typesetting machines and these are the features that Linotype and Machinery Limited have built into this new model.

In newspaper offices where machines must double on tape and manual operation — where four magazines are a must to meet frequent body size changes, where seconds count and where ‘down-time’ must be kept to the bare minimum — the ‘794’ is specified to meet these requirements. But today they are not only the requirements of newspaper offices — general printing is a tough, competitive industry and it needs tough, competitive tools. This is why the ‘794’ has been introduced — and why it will answer the needs of newspaper, jobbing and book houses alike.

The machine, as the name implies, is the natural four magazine development from the very successful high speed model 79, which has become the standard, twelve-lines-a-minute tape-operated ‘Linotype’ in many printing offices all over the world. However, it should be understood that Linotype and Machinery Limited have not merely added two additional magazines to the 79, nor have they merely speeded up the model 78.

The ‘794’ is a new machine with many entirely new features. It incorporates a large number of facilities which are of significant production value. These are of importance in both manual as well as tape operation, and any operator will see immediately how and why.

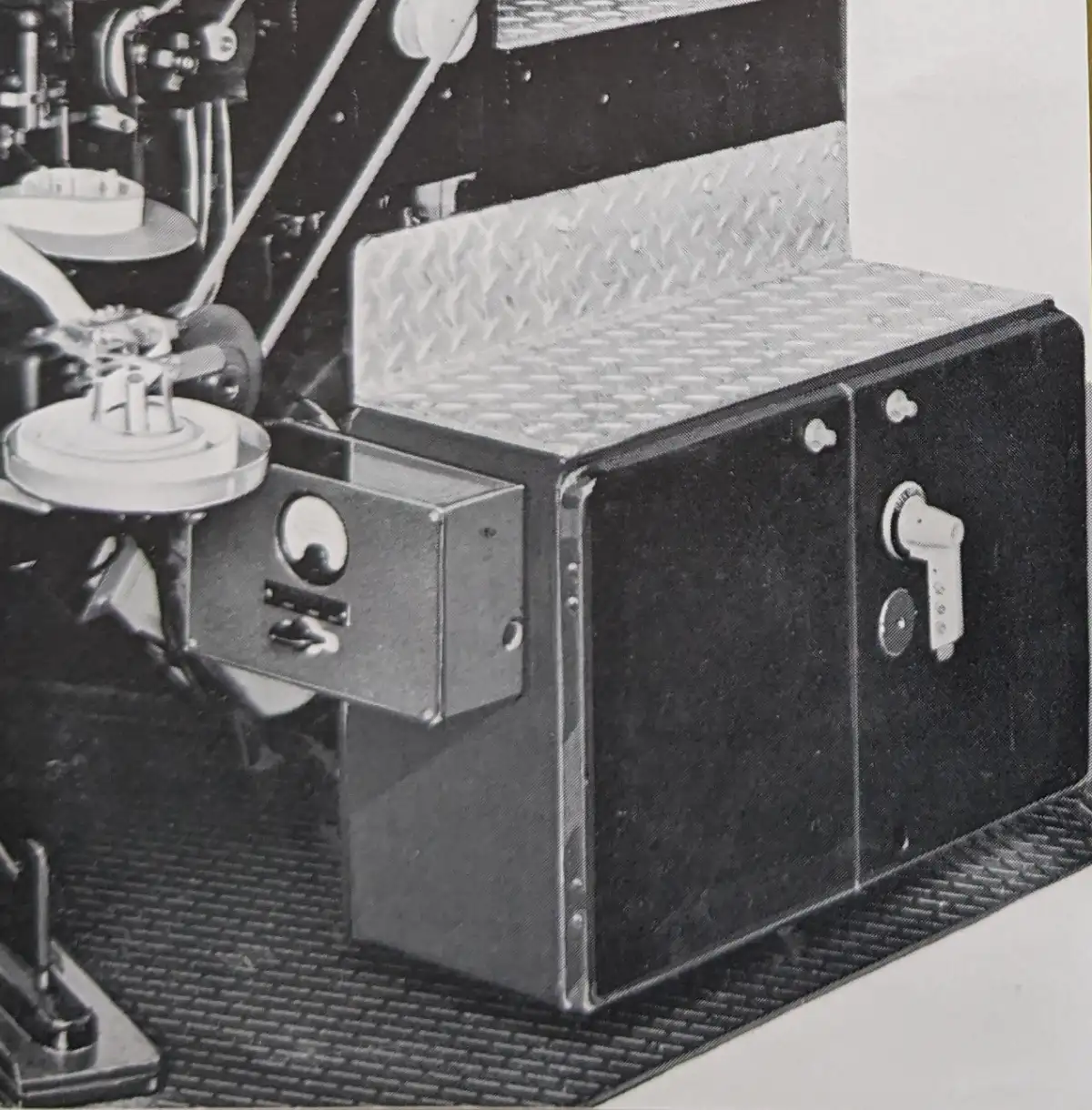

In designing the machine, every effort has been made to bring all controls within easy reach of the operator seated at the keyboard and minimize the amount of effort and time necessary to make the normal changes which are required in ordinary newspaper or general Jobbing production. At the same time, the various essential ‘safeties’ on the standard machine have been considered and in a number of cases improved or redesigned. In particular, the power control box has been split so that all low voltage equipment is in one section of the box entirely separate from the high voltage equipment. There are also a number of special features which are well worth amplifying.

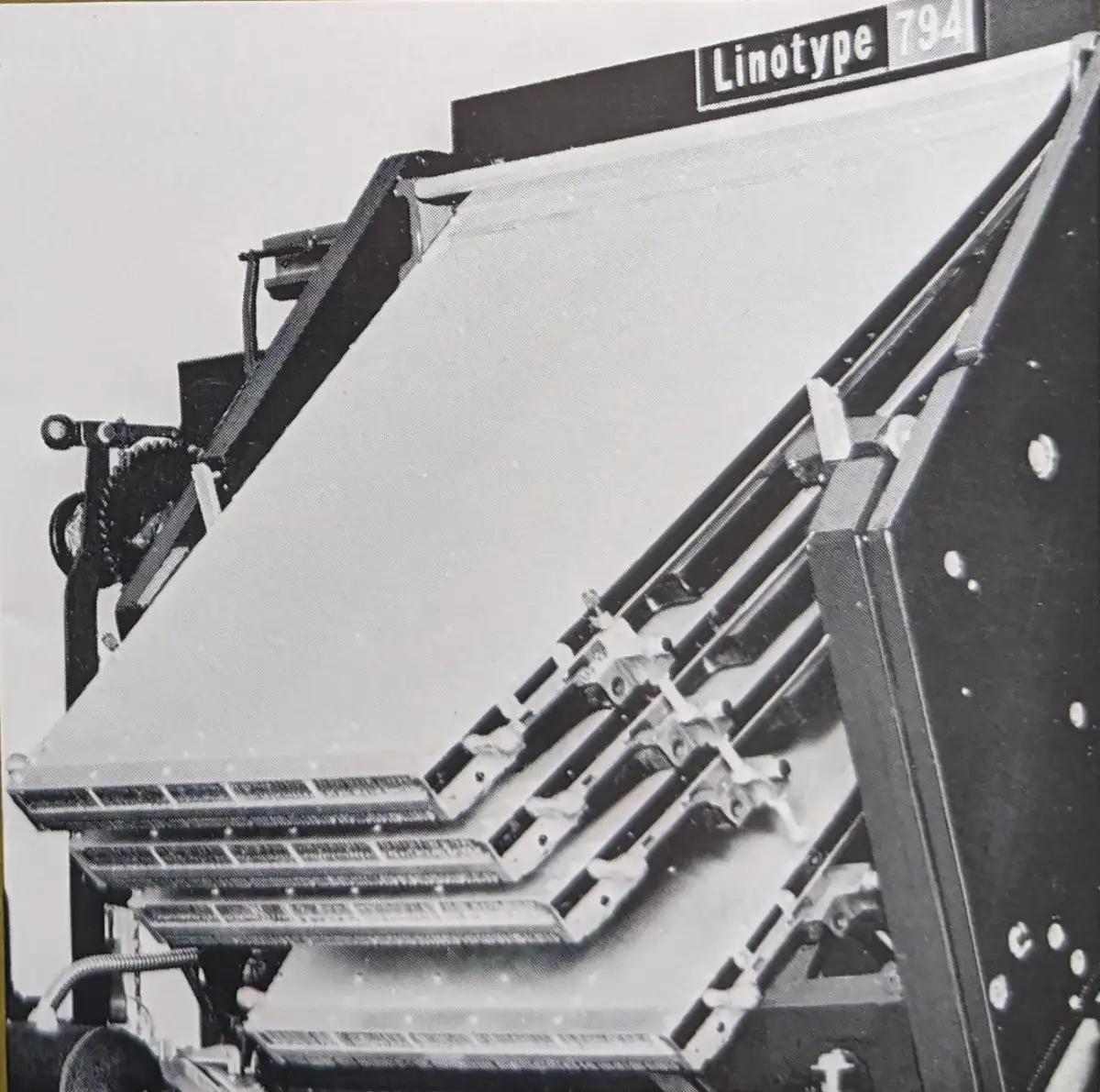

Hydraulic Magazine Change

Selection of each position and spreading is now fully automatic from push button control. Any change, whether from first to second or first to fourth, requires only one operation of the appropriate button. These are situated a few inches above the right-hand side of the keyboard. The new ‘safeties’, which are visually apparent to the operator in a series of lights next to the selection buttons, are completely effective in ensuring that no magazine change is possible while any matrix remains in circulation. This alone will save many pounds in matrix replacement over the year, as well as considerable operator time, as he will no longer have to satisfy himself that the distributor is clear before changing magazines.

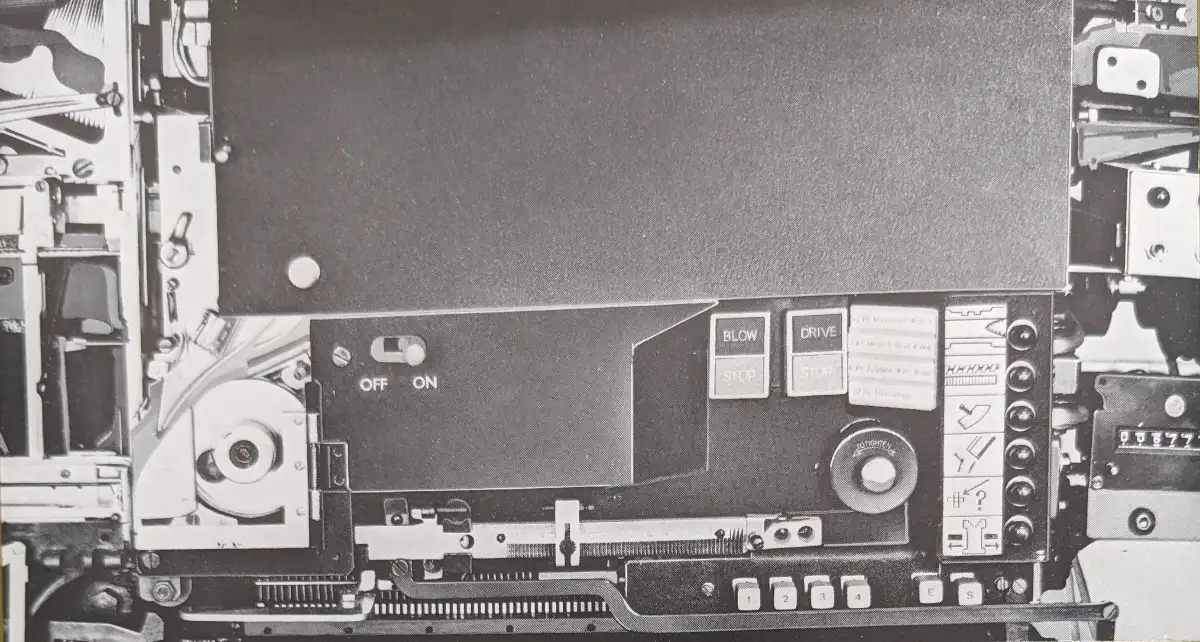

Operator’s Control and the Indicator Console

These are at eye level and virtually at the operator’s fingertips and incorporate all the main machine functions. Machine on/off, Thermo-Blo, Magazine change and indicators, Fount indicators, Assembler spring adjustment and when fitted, the Shaffstall controls and indicators.

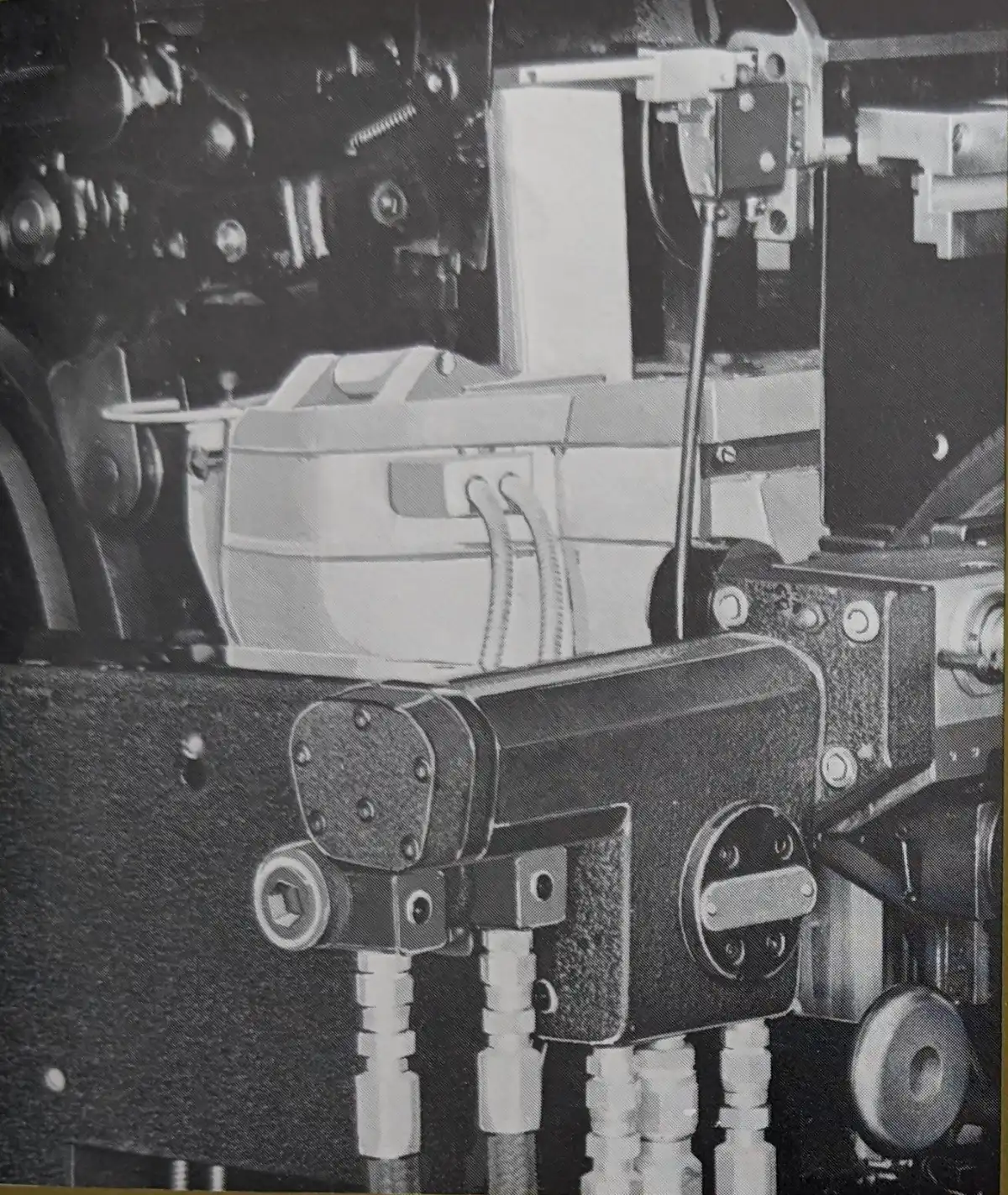

Other Control Points

A new control panel has been introduced immediately to the left, but out of the way, of the operator’s left knee. This includes the air cylinder control, which means that the operator can see the delivery slide and test the adjustment while at the keyboard. The operator is now able to control the full movement of the delivery slide by means of two knobs which operate a double-action air cylinder. In the same panel there is now positioned the mouthpiece temperature control which also indicates by lamp the on/off period of both crucible and mouthpiece. The crucible control box has been simplified and reduced in size, but remains in the normal position, with the same electrical arrangements.

Striker and Keyrods Assembly

This is now one unit and can be removed as such when cleaning.

The Hydraquadder

Incorporates the automatic end of paragraph device which again reduces operator action and is, of course, effective for tape control.

Chute Assembly

This has been stabilized by the addition of a spring loaded flap in place of the feather control, which eliminates periodic adjustment by the operator.

Assembler Brake

This is now fitted with a new return lever at the assembler itself, which enables the operator to release tension in the line when making a character change, with far less effort.

Ejector Lever

This has been redesigned and the lever itself has been strengthened.

Main Cam Guard

This can be applied as an optional extra designed to both protect the operator from the movement of the cams and also incorporate a rail on which to hang up to eight metal ingots.

General Accessibility

The box frame now carries the intermediate shaft drive motor which, apart from removing a general obstruction from the back of the machine, is easily accessible without having to swing the keyboard and assembler front. For reasons of both improved safety and accessibility to the top of the distributor, the whole of the guards at the back of the machine, which are also used as steps, have been redesigned.

Pie-chute and Stacker

This unit, which in the past has always been subject to criticism due to its relatively light construction, has been redesigned. The chute is now a flexible tube which cannot be distorted and cause matrices to jam — and the entrance from the disser is now much more rugged in design.

Special new T.T.S. Features

All ‘safeties’ which become effective during tape operation are now immediately visually defined by the lamp indicators next to the magazine change buttons. This means that immediately the machine stops due to any fault, the operator will be able to locate the cause and make the necessary adjustment with minimum delay.

Automatic Tape Rewinder

For the first time on the Seventy Series range, an automatic, effective and extremely simple tape rewinder is incorporated on the operating unit Cover.