Taken from the book “Operation and Mechanism of the Linotype and Intertype” by J Ashworth, first published in 1955.

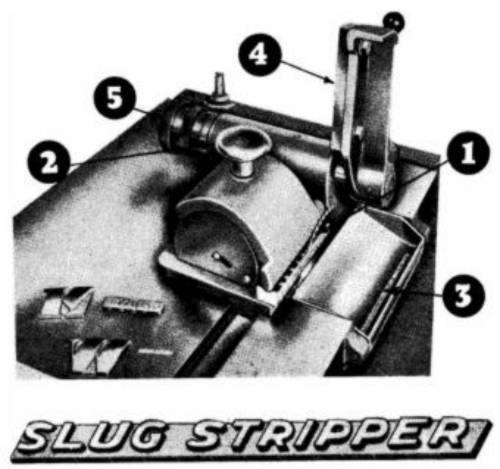

1, a display slug partially stripped; 2, the control knob of the slug-holding clamp; 3, a slug stripped ready for use; 4, the type metal gauge block; 5, the micrometer gauge, calibrated in thousandths of an inch.

To get the correct thickness of trim, the type face of the slug is abutted against a block of type metal 4. The gauge arm, which holds the type metal block, is swung down to horizontal position when gauging a slug for thickness of trim; this is done before taking the cut. The zero position of the gauge 5 is originally established by taking a saw cut off the face of the type metal abutment block 4. The type metal block 4 is easily replaced when it is becoming too thin for further use. BOTTOM: The surface of a Linotype or Intertype slug after stripping

The Morrison Slug Stripper is a simple machine. It consists of a hardened steel, hollow-ground saw blade, and a sliding work table.

The slug stripper cuts the letter characters in a complete strip from Linotype and Intertype slugs, or from any other form of slug or type matter.

The gauge is precision set in thousandths of an inch to trim the stripped type to any required thickness. The work-holding clamp will hold slugs from the thinnest sizes up to 72 point thick, and from a single character to 30 ems long.

The stripped slug or type bearing the letter characters is laid in position directly on the metal base supporting the accompanying illustrations, and is fastened to this base by means of double-coated Scotch tape. In the case of wooden mounts, wider ends on the cast slug permit it to be tacked down, if preferred.

In some forms of work the Morrison Slug Stripper eliminates the need for mortising bases, and inserting type panels; and greatly simplifies the positioning of small panels of type used in conjunction with line blocks and half-tones in catalogue and similar work.