The fascinating story of how a new version of this old machine came to be manufactured in 1960.

Article taken from The History of the Printer by Dr. James Eckman, published in 1965 by North American Publishing Company, Philadelphia, USA.

WHEN the one-time Illinois schoolteacher, John Raphael Rogers, sold his Rogers Typograph Company to the Mergenthaler Linotype Company in 1895 and agreed to become consulting engineer to the Mergenthaler firm, that seemed to be then end of the Rogers Typograph linecasting machine which he had introduced in 1892.

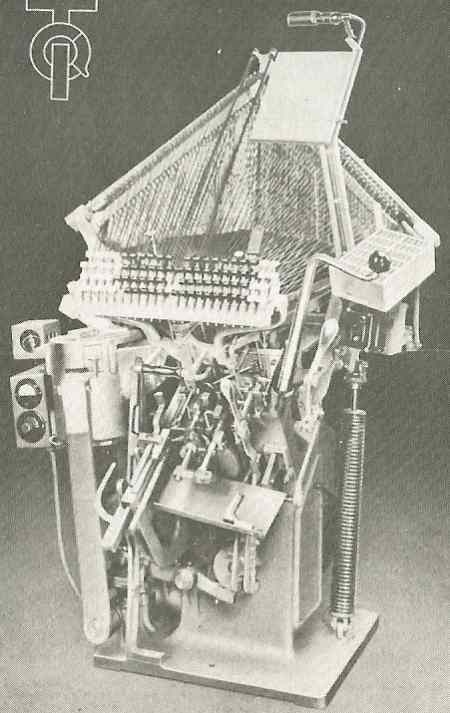

His machine had bar matrices suspended from converging wires strung on a cage form. When the operator pressed a key on the Remington keyboard, a bar matrix slid down one of the inclined wires into casting position; when the line had been cast the operator tilted the cage backward by hand, and the matrices slid back on the wires to remain until needed for the next line.

The slug had no ribs, and only a slight tang on the bottom of the slug was trimmed. The cost of the Typograph was about half that of the simplest Linotype machine.

The Rogers Typograph could not be made and sold in America after 1895, but by 1900 the Canadian Typograph Company, Ltd., of Windsor, Ontario, was making and selling a considerable number of machines in that country. The factory burned, and in 1907, at the expiration of certain Linotype patents, the firm was moved to Detroit, Michigan, where it became known as the American Typograph Company. It was still making Typograph machines as late as 1912, but did not persist long after that year.

In Germany the situation was quite different. Rogers and his machinist, Frederick E Bright, had demonstrated the Typograph in that country in 1894, and the impression was favourable. The Loewe machine works of Berlin made a pilot model in 1895, and a company was formed to market the German Typograph.

This was the Model A, which would set and cast a slug line 16 picas (Cicero) in length and which had one-letter matrices. Subsequently the length of the slug was increased to 24 and then to 26 picas (Cicero).

In 1908 the two-letter Typograph, called the Model B, was introduced. By that year 2000 German Typograph machines had been sold all over Europe.

The Model B had a clutch which would tilt the casting cage backwards automatically after the casting phase. In the original Rogers machine this had been a hand operation.

Next, in 1914, came the Universal Model B Typograph, in which the length of the slug line was increased to 30 picas (Cicero), and in which a rapid-change mold was incorporated. By 1922 the German Typograph organization possessed punches for 984 different letter forms for 35 languages, and in 1934 it was calculated that some 4000 newspapers and magazines had been or were being set on the Typograph.

The machine was simple in construction, efficient and easy to operate. As in the beginning the cost of the machine was about half that of the Linotype. The company was prosperous and its product was in favor throughout Europe and the British Isles when disaster struck in the form of World War II.

The British Lancasters which bombed Berlin into rubble entirely destroyed the Typograph plant in that city. Nothing remained of it.

For almost 20 years the little Typograph linecasting machine was virtually forgotten; then, in 1960, after much planning and great labours, manufacture of the new streamlined Typograph machine resumed.

Today the German Typograph is available once again, with an impressive array of handsome typefaces such as Imprimatur, Centenary Book and Futura from the Bauer foundry at Frankfurt-am-Main; Garamont (sic), Bodoni, Didot and Nefertiti from the Berthold foundry of Berlin; Helvetica from the Stempel foundry at Frankfurt-am-Main; Erbar from Ludwig & Mayer in the same city; and Ile de France from the French Typographic Foundry of Paris.

Once again the ingenious little Typograph linecasting machine introduced by John R Rogers in 1892, and all but forgotten in America for half a century, has come upon the scene in a modern design and with many improvements.

Today any printing office in America can buy it.