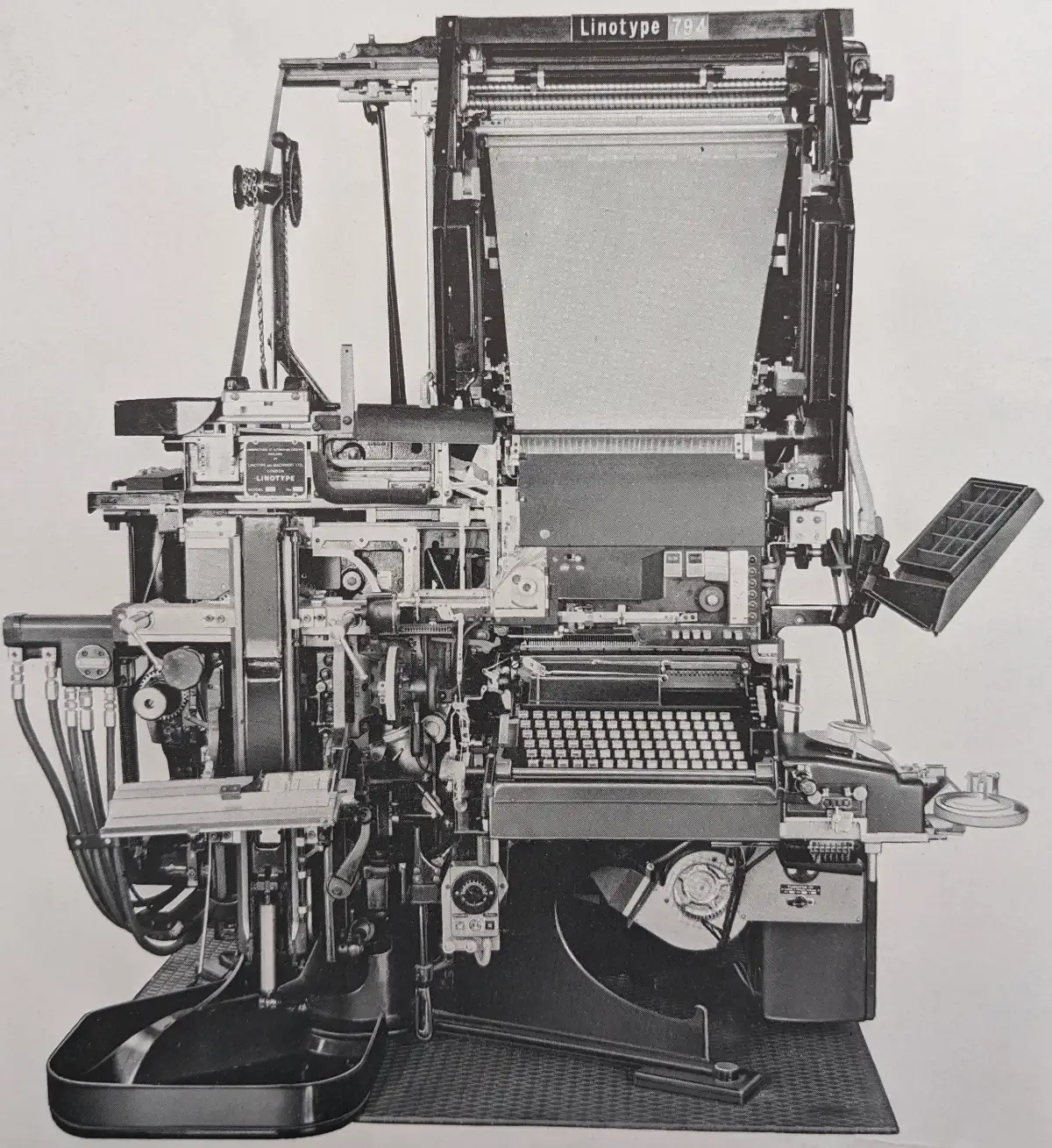

The ‘794’ has been designed to meet the particular requirements of large newspaper offices. It will become the standard all-purpose ‘Linotype’ for three very good reasons.

Reliability

Yesterday’s Technology . . . Today!

The ‘794’ has been designed to meet the particular requirements of large newspaper offices. It will become the standard all-purpose ‘Linotype’ for three very good reasons.

Reliability

The illustrations on this page are from the Ottmar Mergenthaler Museum, digitised by Doug Wilson.

You can read more about how Doug came across these images on the Metal Type forum here: Linotype: The Book.

Many thanks to David Eaves for sending in these photographs, taken in the 1930s, of this commercial general print shop based in Accrington, Lancashire, UK.

David supplied this information on the company: “Jas. Broadley Ltd. were established in 1841 at Clayton-le-Moors, Accrington in North East Lancashire UK.

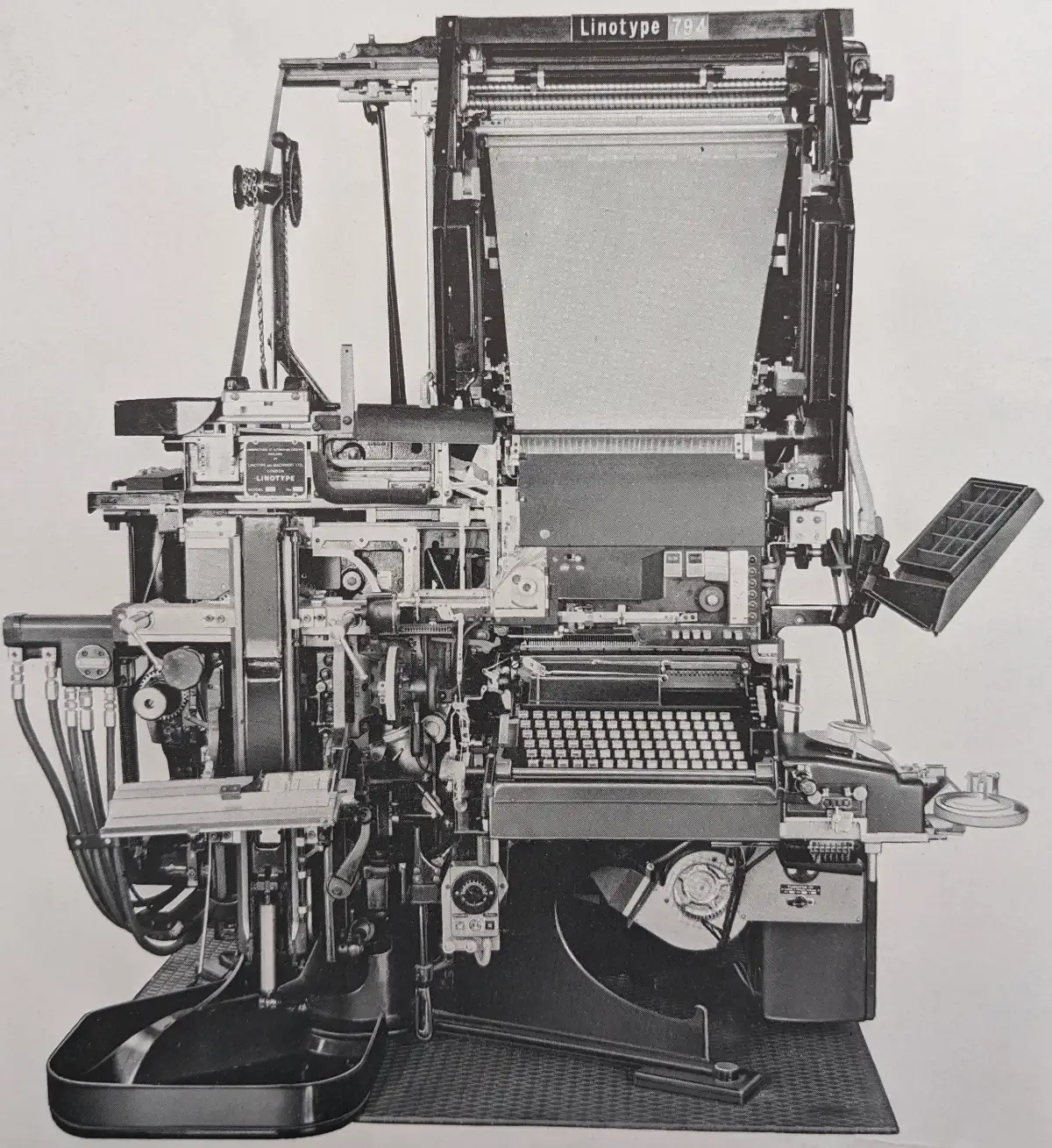

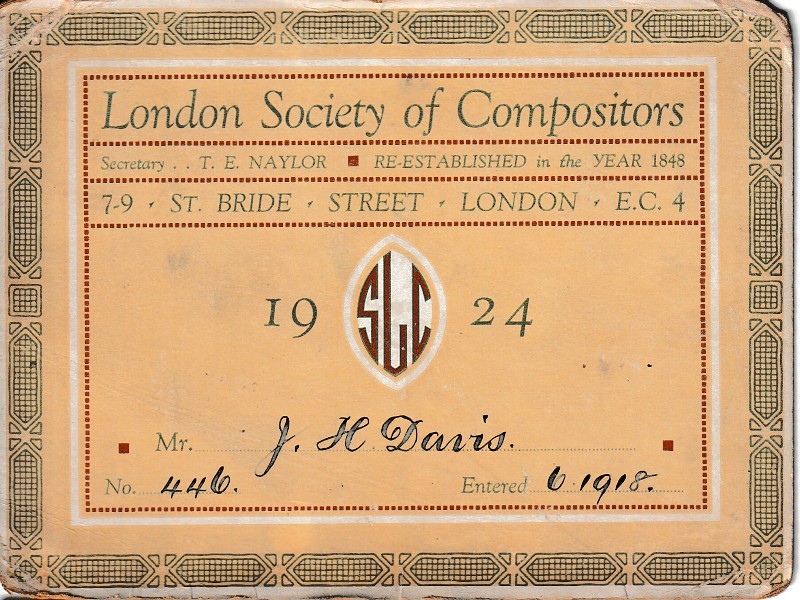

Many thanks to Chris Greenhill for sending in his grandfather’s collection of British Print Trade Union membership cards.

His grandfather Joseph Henry Davis was born in 1884 and entered the print industry at the age of 14. You can read more about his career in London and view his indenture document here: 1898 Indentures.

Many thanks to Chris Greenhill for sending in details of his grandfather’s long career in the print industry, along with his Indenture document, which was signed in 1898.

Chris says: “I gleaned the following from my grandfather’s last surviving daughter, my aunt.

There is some lively discussion about these machines on the Forum.

There are even pictures of some of these machines “in the wild.”

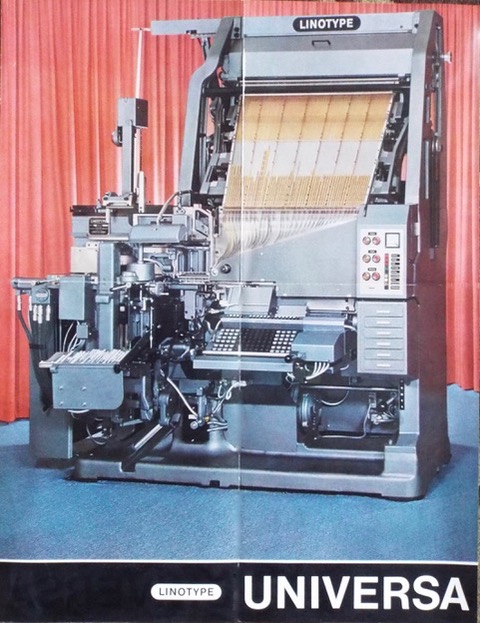

“The latest development in the field of modern setting machine technology” is the heading on the cover of the leaflet promoting the Universa linecaster, one of the very few such machines to be built incorporating a bank of six magazines and which was the impressive leader in the range of “New Line” machines produced during the 1960s by Mergenthaler Linotype GmbH of Frankfurt.

As this 3000kg giant was intended only for manual operation, its casting speed was 8 to 12 lines per minute, and it could be fitted with a mixture of split 72- and 90-channel magazines in various combinations (three of each; two 90s/four 72s; one 90/five 72s, etc) as circumstances demanded. The keyboard automatically adjusted itself according to which type of magazine was in use. Elevation and fanning of the magazines was an electrohydraulic operation to facilitate the mixing operation from four adjacent magazines.

The Continenta could be had as a manually-operated machine offering 28/34/42 Cicero line widths (30/36/42em equivalents) or as a tape-operated version able to cast at speeds of 10 to 15 lines per minute. Weight: 1850kg.

It was a two-magazine mixer utilising standard 90-channel magazines and had a mould wheel with four water-cooled moulds. Hydraquadder and Mohr saw could be added as extras to the basic specification and the machine shown in the colour illustration is thus equipped.

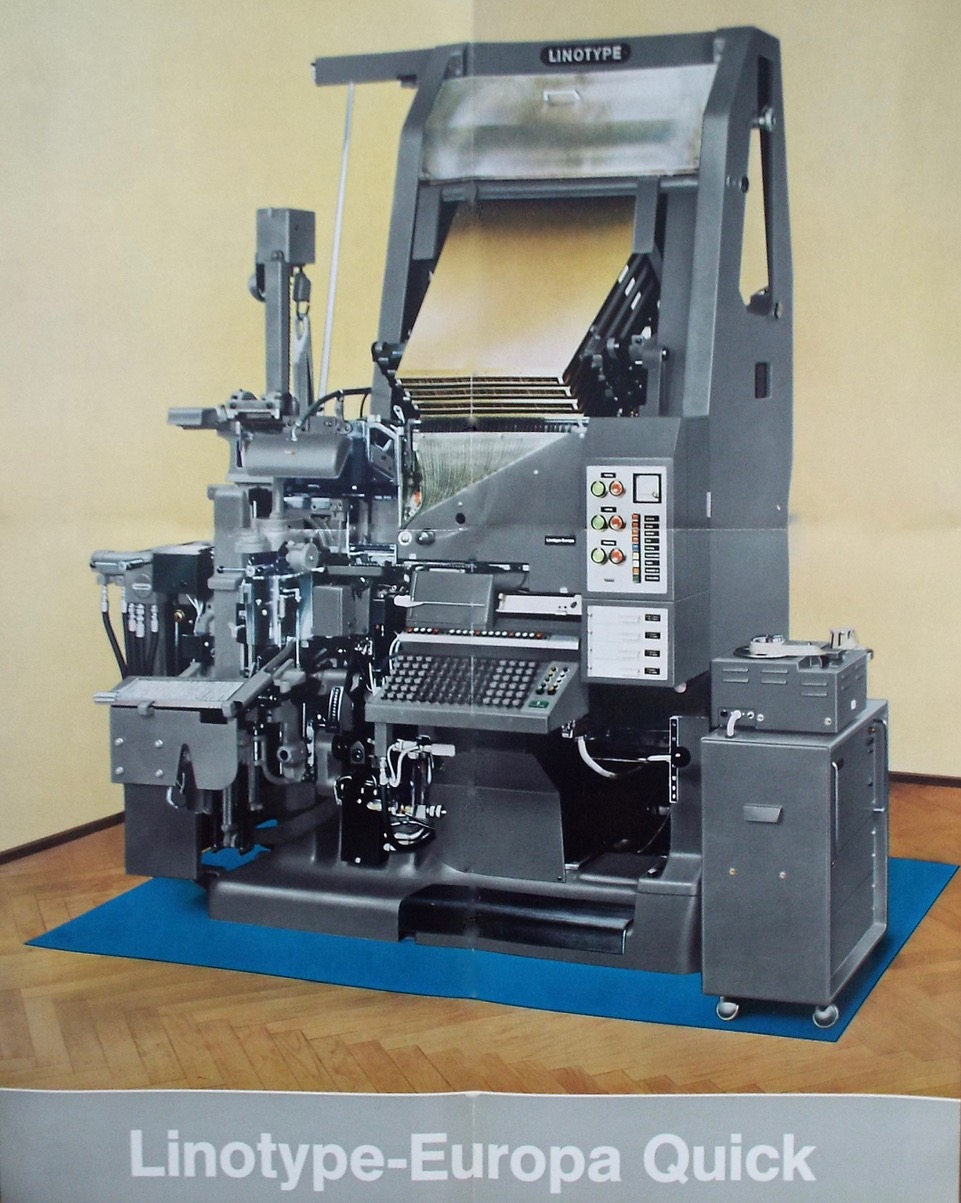

There were two versions of this design, the original and the Europa G Quick, both of which were designed principally for high-speed tape operation but which could also be used manually.

As regards the first-mentioned, it was a four-magazine mixer weighing-in at 2000kg equipped with four water-cooled 28 Cicero (30em) moulds, with provision for extension to 34 Cicero (36em) operation. Magazines were 90-channel configuration. Hydraquadder and Mohr saw could be had as extras and the remarks previously given regarding provision of these features applies again.