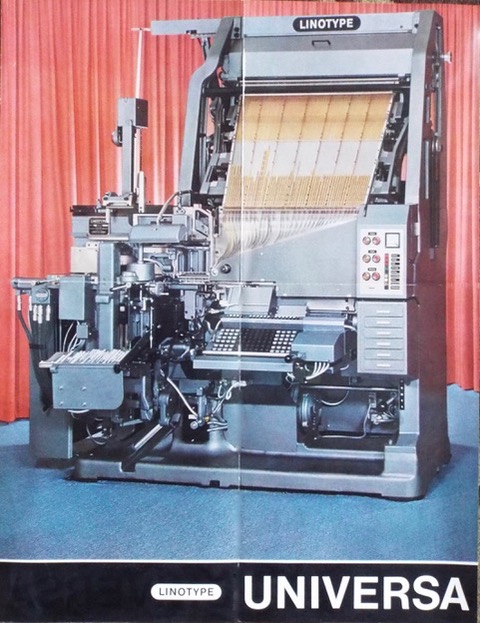

“The latest development in the field of modern setting machine technology” is the heading on the cover of the leaflet promoting the Universa linecaster, one of the very few such machines to be built incorporating a bank of six magazines and which was the impressive leader in the range of “New Line” machines produced during the 1960s by Mergenthaler Linotype GmbH of Frankfurt.

As this 3000kg giant was intended only for manual operation, its casting speed was 8 to 12 lines per minute, and it could be fitted with a mixture of split 72- and 90-channel magazines in various combinations (three of each; two 90s/four 72s; one 90/five 72s, etc) as circumstances demanded. The keyboard automatically adjusted itself according to which type of magazine was in use. Elevation and fanning of the magazines was an electrohydraulic operation to facilitate the mixing operation from four adjacent magazines.

Imagine what a variety of setting could be undertaken when being given the chance to mix from four magazines and a range of type sizes from 6pt to 42pt or even 48pt (cast overhanging on a 42pt slug): the mind boggles! German Linotype even offered several 16pt and 20pt faces such as Times and Helvetica, and to cast on both alignments it was necessary for the machine to be fitted with a special 16–20pt mould so that these useful “in between” sizes could be brought into play. (In America, Linotype had a few 16pt faces available but these were made as single-letter mats due to the difficulties in casting from the auxiliary alignment. Intertype did a bit better: they offered a few double-letter 16pt faces and a mould to suit.) Distribution was dealt with through five sets of distributor screws (though the top set was only long enough to clear the first distributor box and pie shute).

The mould wheel contained six pockets and could cast from 6pt to 42pt up to a measure of 28 Cicero (30ems), which was the longest length that could be accommodated on a six-pocket mould wheel. Hydraquadder and Mohr saw came as standard fitments and would be essential in view of the extremely varied range of work that this Lino could undertake. Push-button control for the quadder, mould wheel and magazines was provided above the keyboard.

For the first time since we looked at the Delta machine the operator has a normal hand-lifting mechanism for the assembling elevator, rather than the push-button control on all the other machines, and it’s useful also to point out how the side-case matrices were accommodated in six neat drawer compartments located to the right of the keyboard, just below the array of operating buttons, warning lights and temperature gauge which one imagines would be an ever-changing wonder when the beast was operating!

I am bound to wonder if the operator’s attention would sometimes be distracted by the sight of mats as they emerged from the magazine and were then very visible as they dropped on to the assembler belt. English Linotype developed what it called its “optic-aid” front plate which hid all this activity from the operator’s peripheral field of vision. I think the cascade of mats would have distracted me!

What a machine, and it is pleasing to know that one is preserved in working order at the Haus für Industriekultur in Darmstadt in Germany alongside other “New Line” machines, plus a vast range of other Linotypes, Intertypes and Neotypes in addition to single-letter casting machines and much else of interest to students of typecasting in its many different forms.

This monster was surely an impressive end to linecaster development not only in Germany but in the entire world. It would be interesting to learn how many were actually sold, as the price must have been high, and the fact that the Universa arrived very late in the day for hot metal setting would also act against its widespread use. Did the Russians copy it? Not that I am aware—but should anyone know otherwise, Metal Type would be very interested to hear from them!