Check the “Related Pages” menu for further reading on Russian linecasters.

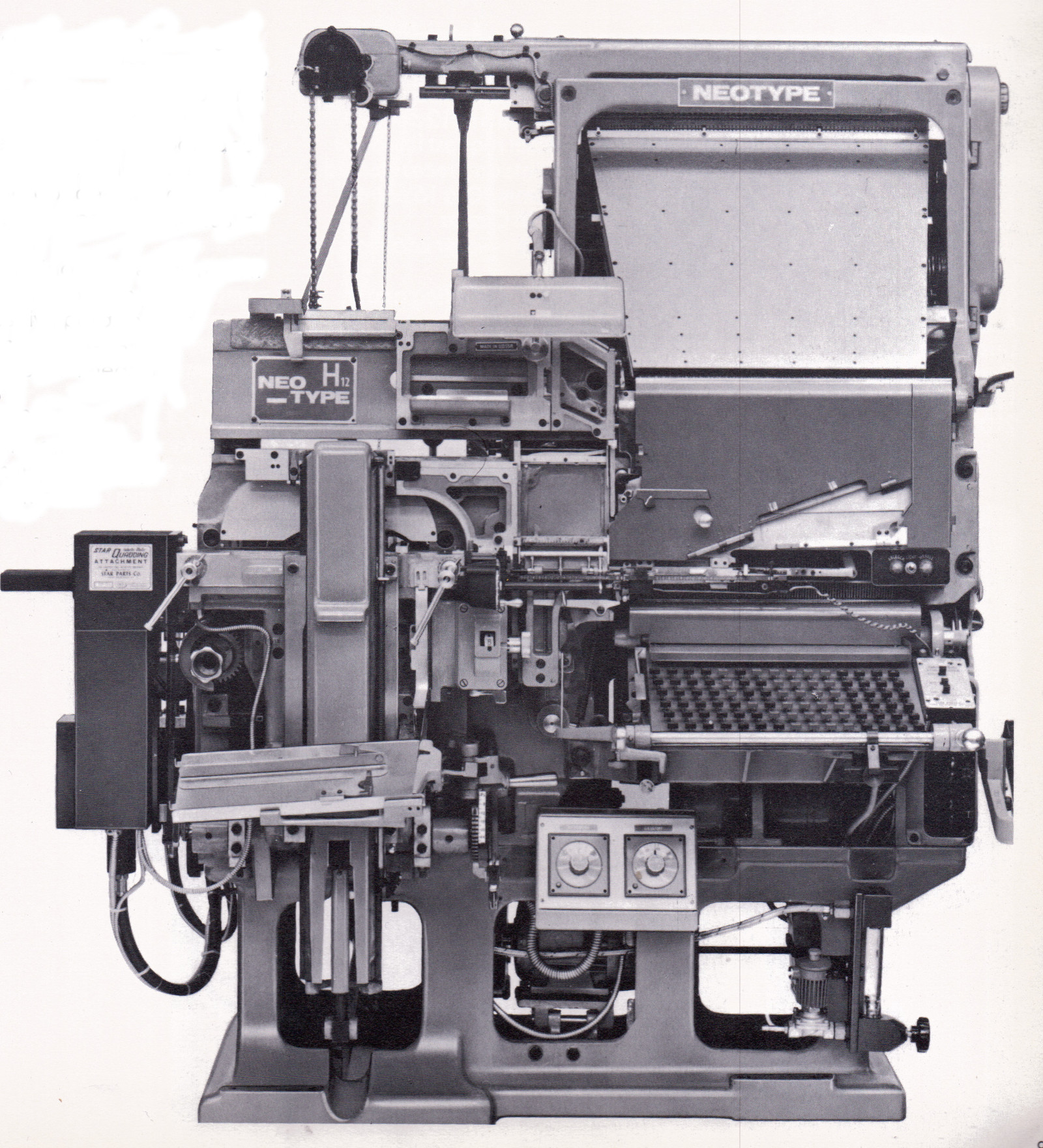

The following pictures and descriptions come from an un-dated glossy brochure produced by Neotype, West Germany.

The Compact Series

Function and reliability of a good typesetting machine are dependent on construction and design.

Neotype typesetting machines have been built by Europe’s largest typesetting machine manufacturer over a period of 40 years. They are in operation throughout 70 countries under the most different working conditions.

Neotype typesetting machines are the result of a successful, constructive design, guaranteeing easy operation, a maximum of operational safety, problemless maintenance, reliability and a first class setting performance. In addition, Neotype typesetting machines are designed so as to permit the use of magazines and matrices of all makes on the market.

Neotype typesetting machines offer compact advantages: a clear design, reduced floor space requirements, easy access to all movable parts, reduced maintenance requirements and economical operation. The cost-performance ratio is such that any printer can afford it. Neotype typesetting machines are suitably fitted in their own assembly plant in Cologne according to the specific wishes of the clients and in line with the requirements of world markets.

Guarantee for a Maximum of Setting Performance

The Clutch. The clutch is very handy for the composer. In case of eventual breakdown easy operation with the hand-wheel turns it back to neutral position. No problems at all.

The assembling elevator. The assembling elevator goes automatically upwards as soon as the key is pressed down. The line is sent off or the blank line is already casted (H121, H122, H124).

The mould wheel. Change of size takes 35 seconds. Four universal moulds are available. Recess moulds with 12, 16 and 20 points. The combined air and water cooling system keeps the operation temperature constant and prevents from corrosion.

Magazine position. Inclination angle of the magazines is 67 degrees. The resulting high falling speed makes for a high setting performance (H121, H122, H124).

The quadding and centering decice. STAR-PARTS quadding and centering device. This combination of hydraulics and electro-magnets guarantees a minimum of maintenance and wear.

The front-plate frame. Matrices are liable to jamming. On the Neotype machine you only need to swing down the sheet covers. Then the magazine outlet and the assembler friction lie open in front of the composer. The front-plate frame can also be swung out, giving access to the bar frame.

The curve eccentric. The compact design is not only space saving. The Neotype machine is provided with one single justification lever. This means there are two curves less needing maintenance and care.

The switch board. The electronic part is uncomplicated and robust, guaranteeing correct function and correct transmission of all orders that are received from the keyboard (H140).

The maintenance service. All protection devices of the Neotype machine can be opened without difficulty. The entire mechanical system is easily accessible.

Magazine reversal. By pressing down a lever, the magazine moves hydraulically into position. Furthermore, a safety rail prevents the magazines from moving in case of jamming (H124).

The assembler. Fluent operation due to the non-stop assembler, the electro-magnets used for the switch-over into the medium faced position and the low maintenance requirements of the nylon gear wheel and disks. Guarantee to resist highest strain (H140).

The elevator. One single lever is used for transporting the matrices on the rack bar of the second elevator, moving subsequently the keys into the key-box.

Magazine adjustment. Sometimes magazines may get out of position. On the Neotype machine it is possible to adjust them in horizontal and vertical direction. Furthermore: the magazine is provided with a safety-rack disengaging immediately the distributor spindle whenever the matrices fall down in a transverse or bevel position. (H121, H122, H124, H140).

Neotype H12

Two-magazine typesetting machine. 4 universal casting moulds point size from 6 to 12 points. Small magazines, with 15 matrices per channel, only upon special request, recess moulds point size from 10 to 12 points. Slug up to 28 Cicero. Upon request combined air-water cooling system and STAR-PARTS quadding and centering device.

Performance: 7 slugs per minute. Weight 950kg. 1.170mm wide, 1.300mm deep, 1.700mm high.

Neotype H121

Single-magazine typesetting machine. 4 universal casting moulds. Point size from 6 to 12 points. Upon special request fitted out with 16 points and recess mould. Point size from 10 to 16 points. Slug up to 28 Cicero. Combined air-water cooling system. STAR-PARTS quadding and centering device.

Performance: 9 slugs per minute. Weight 1,400kg. 1.360mm wide, 1.270mm deep, 2.100mm high.

Neotype H122

A two-magazine typesetting machine. 4 universal casting moulds. Point size from 6 to 12 points. Upon special request fitted out with 16 points and recess mould. Point size from 10 to 16 points. Slug up to 28 Cicero. Combined air-water cooling system. STAR-PARTS quadding and centering device.

Performance: 9 slugs per minute. Weight 1,200kg. 1.360mm wide, 1.270mm deep, 2.100mm high.

Neotype H124

Four-magazine typesetting machine. 4 universal casting moulds. Type size from 6 to 12 points. Upon special request fitted out with 16 points and recess mould. Type size from 10 to 16 points. Slug up to 28 Cicero. Combined air-water cooling system. STAR-PARTS quadding and centering device.

Performance: 9 slugs per minute. Weight 1,400kg. 1.360mm wide, 1.270mm deep, 2.100mm high.

Neotype H140

A four-magazine typesetting machine, prepared for TTS. 4 universal casting moulds. Point size from 6 to 20 points. Upon special request point size up to 24 points with recess mould. 12 to 24 point size. Slug up to 28 Cicero. Combined air-water cooling system. STAR-PARTS quadding and centering device.

Performance: 11 slugs per minute. Weight 1,900kg. 1.900mm wide, 1.750mm deep, 2.200mm high. STAR-PARTS Auto-Setter.

Neotype L136

Slug and lead casting machine. Point size: Leads 1 to 16 points; Slugs 2 to 24 points; Webs 24 to 36 points. Length up to 150 Cicero. Performance p/h: Depending on point size up to 25kg. Water cooling system. Exchangeable casting moulds, adjustable web length, automatic cutting device, electronic temperature regulator. Maximum advance movement 8 Cicero, minimum advance movement about 1 Cicero.