Category: Composition

Later Machines

Illustrations and machine descriptions of Models 8 to 26 are from a pamphlet called “Linotype Flexibility” published by the Mergenthaler Linotype Company in 1930. Models 28 to 32 from “Linotype Machine Principles” published in 1940.

Linotype fan? Don’t miss the Linotype Chat section of the Metal Type Forum.

Welcome to Metal Type

METAL TYPE is the place for printers, typesetters and newspaper workers, who fondly remember those letterpress days, to come and reminisce.

The site originally concentrated on the ingenious Linotype mechanical typesetting machine invented by Ottmar Mergenthaler in 1884.

Linotype Model 6

The model 6 was specially designed for the production of work requiring a variety of type faces mixed in one and the same line, such as catalogues, encyclopaedias, dictionaries, etc.

It is equipped with four main magazines and two distributors.

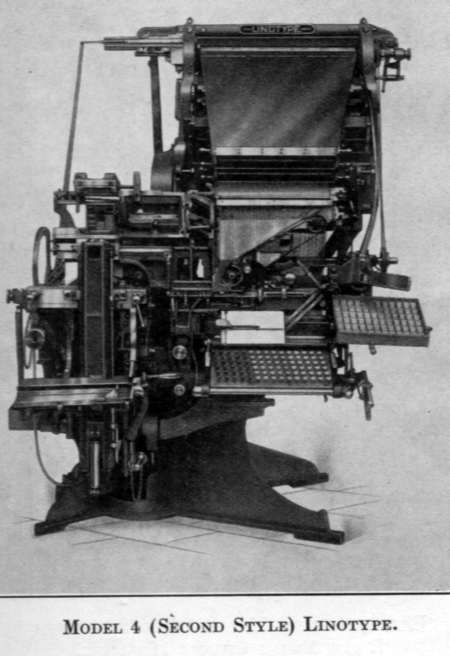

Linotype Model 4 (Second Style)

The new Model 4 is the standard three-magazine machine, and is so constructed that a side display section can be added at any time.

It is fitted with all the labour-saving devices which have been developed to date, with the result that the machine provides the most perfect and economical composing equipment within its capacity.

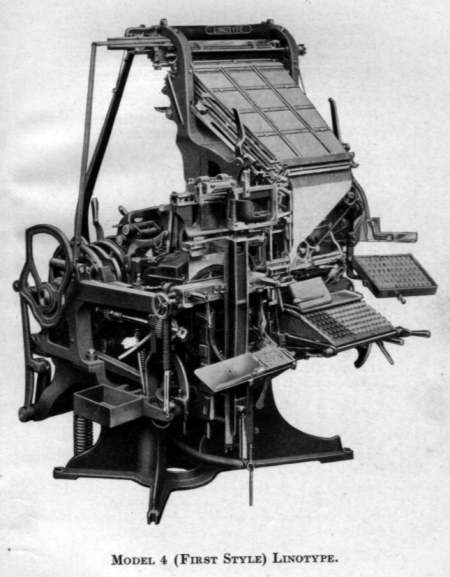

Linotype Model 4 (First Style)

This model increased the capacity of the Linotype machine, enabled the operator to effect a quick change from one magazine to another, and from one mould to another, without getting off his chair, and provided a composing machine suitable for general jobbing as well as the newspaper printer.

With three magazines in position, each charged with double-letter matrices, and with the necessary moulds in the mould wheel, this model was capable of turning out work of varied character at the highest possible speed.

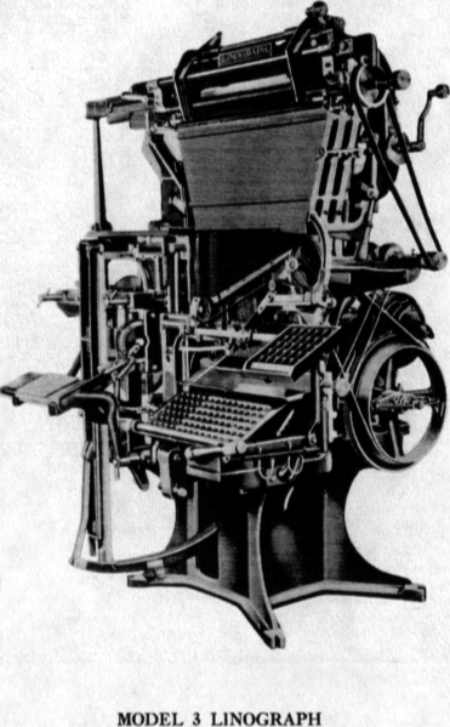

The Linograph

The basic patent on a combined assembling, casting and distributing machine granted to Ottmar Mergenthaler on 12 May 1882, expired in 1902 and the Mergenthaler patent on the Schuckers expandable wedge spaceband expired in 1909. Certain other Linotype patents became void soon after 1909.

By 1912 it was legally possible for anyone with sufficient capital to manufacture a machine that would assemble and cast lines of type.

Linotype Model 3

Principal Features:

This machine had two magazines always in position, and each magazine contained a complete set of double-letter matrices, all of which could be used in a single line, set from one keyboard. It was the first double-letter distributor Linotype.

Linotype Model 2

This machine had the following improvements over the Model 1 (Old Style):

A light magazine, capable of being changed from the front of the machine.

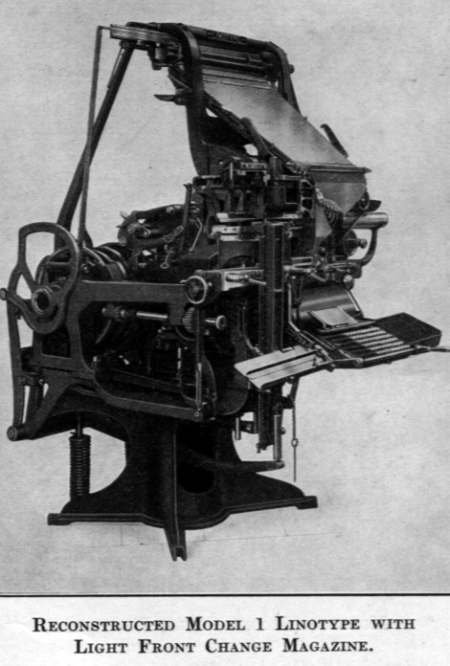

Reconstructed Linotype Model 1

Reconstructed Model 1 Linotype with Light Magazine.

This machine produced type faces and bodies up to 14-point, in any measure up to 30 ems.

It was fitted with a light magazine which slid off the front of the machine so that another magazine could be substituted.